Spider

CT Repair

wc_tx000553gb.fm

86

7.6

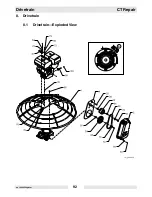

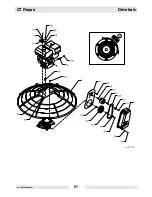

Removing the Spider

See Graphic: wc_gr003154

Disconnect or remove the spark plug to avoid accidentally starting the

engine when turning the trowel blades. See section

Engine Wiring

.

This procedure requires an appropriate hoist or crane to lift the trowel.

7.6.1

Pitch the blades so they lie flat (0° pitch).

7.6.2

Remove the lock nut from the bottom of the pitch control cable.

Disengage the pitch control cable from the yoke.

7.6.3

Remove the clevis pin

(43)

and the cotter pin

(45)

to release the yoke

(12)

from the gearbox. Slide the yoke free of the guard ring.

7.6.4

Lift the trowel by the lifting eye to gain access to the underside of the

spider.

The trowel arms are free to rotate. Be careful when handling the trowel

to avoid pinching your hands or fingers between the trowel blades.

7.6.5

Remove the arms from the spider. See section

Replacing the Arms.

7.6.6

Remove the cap plug

(40)

from the bottom of the spider.

7.6.7

Carefully hold the trowel arms in a stationary position. Remove the

screw

(55)

and the washer

(72)

that secure the spider to the output

shaft. Pull the spider assembly from the output shaft.

7.6.8

Remove the blade lift ring assembly

(9

,

10

,

28

,

88)

from the spider

(8)

.

WARNING

WARNING

Summary of Contents for CT 36

Page 2: ......

Page 12: ...Safety Information CT 36 CT 48 wc_si000139gb fm 12 1 5 Label Locations...

Page 29: ...CT 36 CT 48 Operation wc_tx000373gb fm 29 wc_gr001758 e f g h j k...

Page 53: ...CT 36 CT 48 Maintenance wc_tx000374gb fm 53...

Page 59: ...CT Repair Guide Handle wc_tx000551gb fm 59 wc_gr003361 1 2 a e d c b...

Page 60: ...Guide Handle CT Repair wc_tx000551gb fm 60 5 3 Upper Handle Twist Pitch Control Exploded View...

Page 63: ...CT Repair Guide Handle wc_tx000551gb fm 63 wc_gr003360 a d f b h g c d e...

Page 65: ...CT Repair Guide Handle wc_tx000551gb fm 65 wc_gr003363 g a d e b f c...

Page 68: ...Guide Handle CT Repair wc_tx000551gb fm 68 Notes...

Page 75: ...CT Repair Clutch wc_tx000552gb fm 75 wc_gr003364 a b wc_gr002068 2 3 4 5 7 6 8 1...

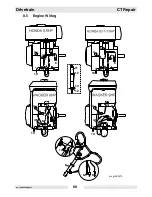

Page 78: ...Spider CT Repair wc_tx000553gb fm 78 7 Spider 7 1 Spider Assembly Exploded View...

Page 81: ...CT Repair Spider wc_tx000553gb fm 81 wc_gr003365 a b...

Page 83: ...CT Repair Spider wc_tx000553gb fm 83 wc_gr003356 a b c e d x x x x x x 180 g f i h...

Page 85: ...CT Repair Spider wc_tx000553gb fm 85 wc_gr003357 x a c d b 1 2 3 4...

Page 87: ...CT Repair Spider wc_tx000553gb fm 87...

Page 89: ...CT Repair Spider wc_tx000553gb fm 89...

Page 91: ...CT Repair Spider wc_tx000553gb fm 91 wc_gr003358 88 28 28 10 10 11 59 9 9 27 27...

Page 92: ...Drivetrain CT Repair wc_tx000554gb fm 92 8 Drivetrain 8 1 Drivetrain Exploded View a...

Page 95: ...CT Repair Drivetrain wc_tx000554gb fm 95 a...

Page 97: ...CT Repair Drivetrain wc_tx000554gb fm 97 a...

Page 103: ...CT Repair Drivetrain wc_tx000554gb fm 103 wc_gr003359...

Page 104: ...Drivetrain CT Repair wc_tx000554gb fm 104 8 10 Gearbox Exploded View wc_gr003367 93 94 1...

Page 107: ...CT Repair Drivetrain wc_tx000554gb fm 107 20 e f 29a 29b 18 6 89 d c 29a 33 87 wc_gr003157...

Page 109: ...CT Repair Drivetrain wc_tx000554gb fm 109 b a 19 29 35 32 wc_gr003366 93 94 22 94 29 30 30 g h...

Page 111: ...CT Repair Drivetrain wc_tx000554gb fm 111 wc_gr003367 93 94 1 wc_gr003368 a...

Page 112: ...Drivetrain CT Repair wc_tx000554gb fm 112 Notes...

Page 117: ......