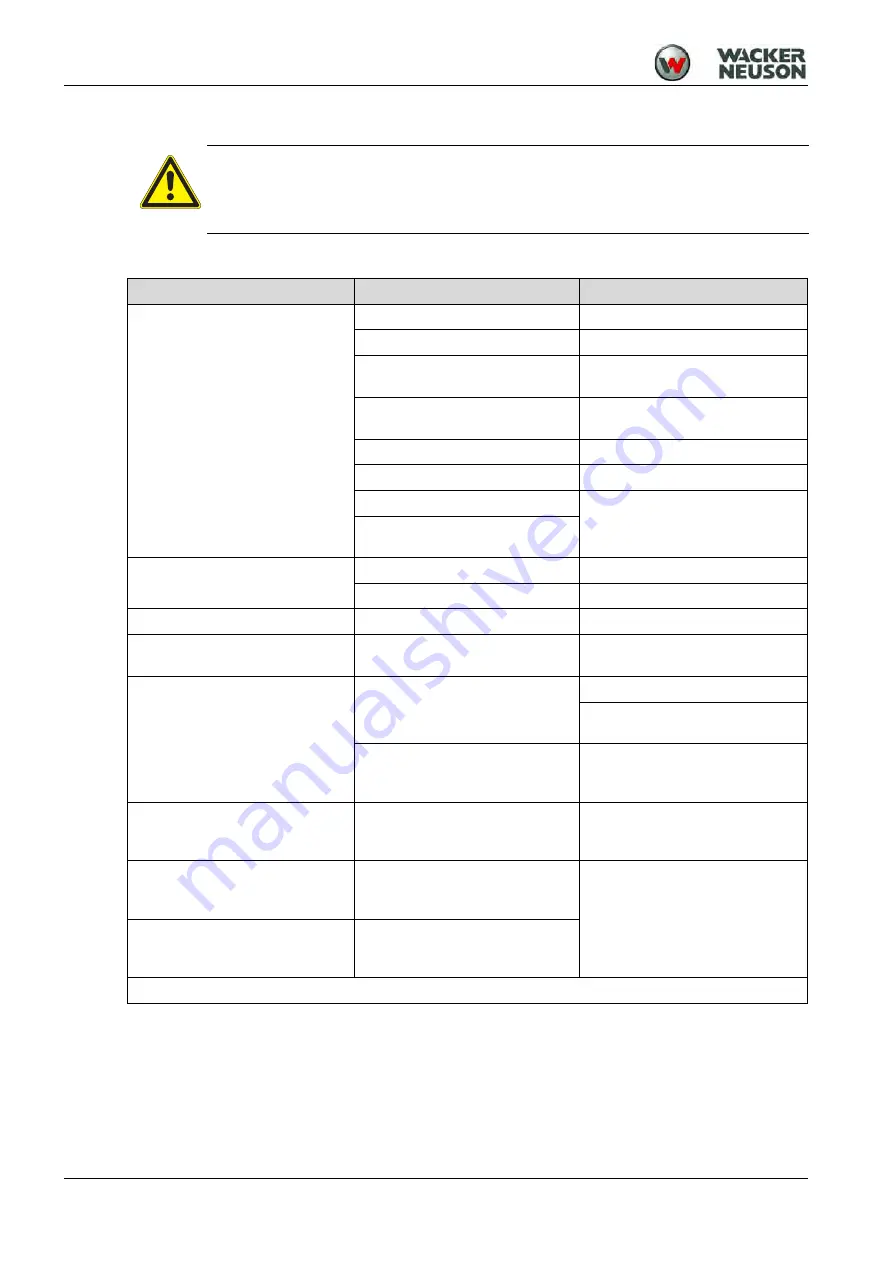

10 Troubleshooting

52

100_0202_ts_0010.fm

10 Troubleshooting

10.1

Troubleshooting table – machine

DANGER

Danger to life from unauthorized troubleshooting.

If faults occur with this machine that are not described in this manual, contact the

manufacturer. Do not eliminate the faults independently.

Fault

Possible causes

Remedial measure

Motor will not start.

Emergency stop switch is pressed.

Unlock emergency stop switch.

Machine is not activated.

Activate machine.

Discharge starter battery.

Load starter battery or perform

jump-start with donor starter.

Low oil level

Top up oil and actuate valve hood

on the oil filter housing.

Low fuel.

Top up fuel.

Fuel filter is dirty.

Replace fuel filter.*

Defective starter motor.

Have the machine repaired.*

Remote control, decoder, or wiring

harness is defective.

Engine runs unevenly.

Fuel filter is dirty.

Replace fuel filter.*

Air cleaner is dirty.

Clean or replace air cleaner.

Vibration will not start.

Electrical system defective.

Have the machine repaired.*

Engine smokes and does not

perform.

Air cleaner is dirty.

Replace air cleaner.

Machine cannot be activated.

Incorrect activation PIN entered.

Enter the correct activation PIN.

Deactivate machine with

emergency stop switch.

Electrical system defective.

1. Deactivate machine with

emergency stop switch.

2. Have the machine repaired.*

Diagnostics menu cannot be called

up.

On / off switch of the machine not

pushed long enough.

Continuously press the ON/OFF

switch of machine for at least three

seconds.

Compatec display unit (optional):

Light progress bar does not appear

upon initialization.

Compatec display unit or wiring

harness defective.

Have the machine repaired.*

Compatec display unit (optional):

Short lighting up of all LEDs does

not occur upon initialization.

Overload sensor or electrical

connection is defective.

*

Have this work performed by the service department of your Wacker Neuson contact partner.

Summary of Contents for DPU80 Series

Page 74: ......