9 Maintenance

44

100_0202_mt_0011.fm

9.2

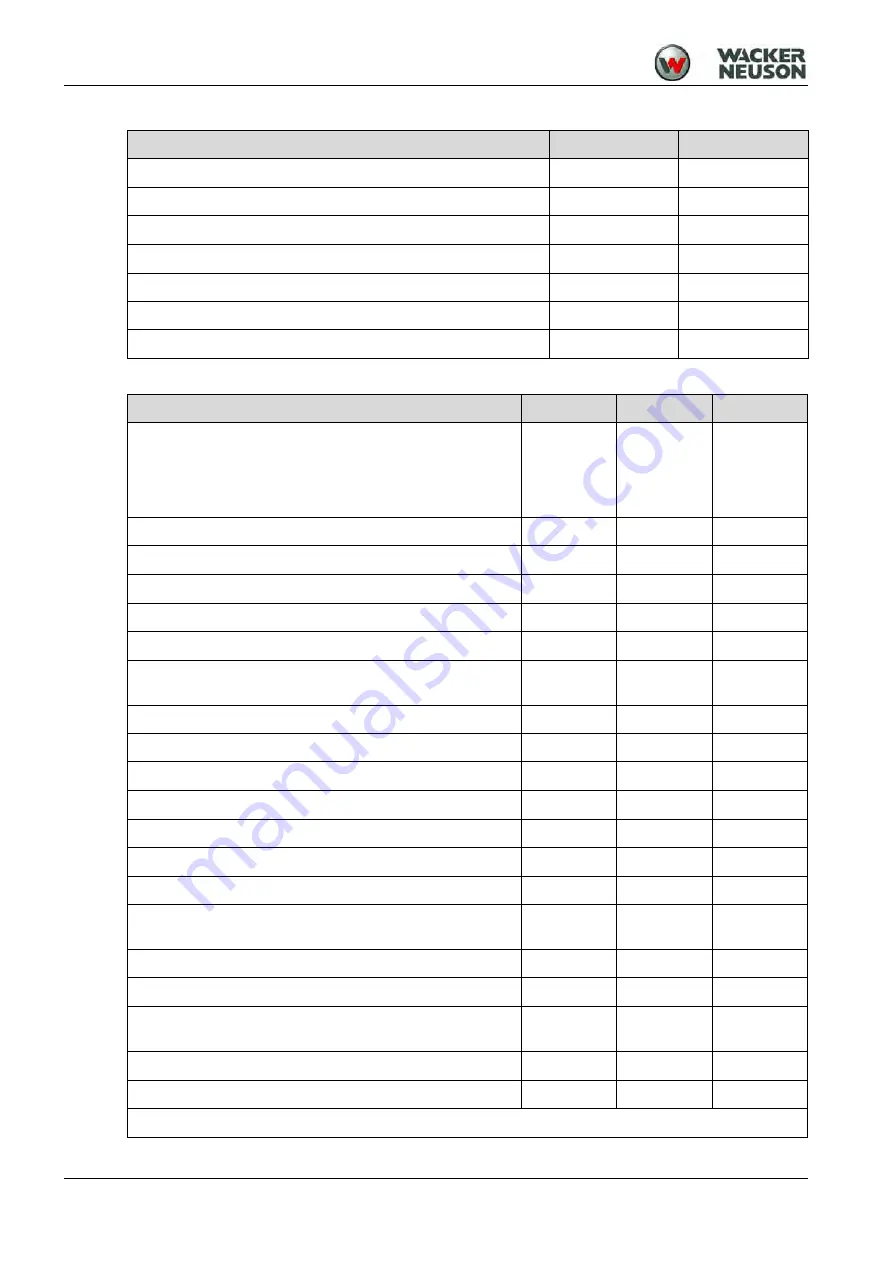

Maintenance schedule – daily maintenance jobs

9.3

Maintenance schedule – regular intervals

Maintenance jobs

before operation

after operation

Inspect for completeness.

Visual inspection for damage and leaks.

Check engine oil level and top off if necessary.

Check coolant level and top off if necessary.

Check radiator for dirt and clean if necessary.

Check the operation of the emergency stop switch.

Clean machine and remote control.

Maintenance jobs

every 125 h

every 250 h

every 500 h

Make sure the screwed connections are firmly seated:

Center brace.

Central lifting point.

Hydraulic tank.

Rubber buffer of the base plate.

Check exciter oil level.

Check hydraulic oil level.

Check hydraulic hose lines.*

Check hydraulic oil level on the center pole.

Check the rubber buffer of the base plate.*

Check function of the proximity recognition sensor (remote

control).

Lubricate latches of the protective hood

Check central lifting point for damage.

Replace engine oil and oil filter of the drive motor.

Replace fuel filter.*

Check coolant hoses and clamps.*

Check anti-frost layer of radiator

Check the hosepipes and clamps of the air intake system.*

Replace air cleaner cartridge.

If the control lamp lights up, even before reaching the interval.

Replace exciter oil. *

Check the V-belt of the generator – tighten *.

Check the rubber buffers on the protective hoods, hinges and

locks for pretension.

Replace the hydraulic oil filter with air cleaner.*

Check the tapped clearance, adjust if necessary.*

*

Have this work performed by the service department of your Wacker Neuson contact partner.

Summary of Contents for DPU80 Series

Page 74: ......