Table of Contents

E 1100

wc_bo5200003474_02TOC.fm

7

7.6

Repairing a Hose ................................................................................ 94

7.7

Inspecting Electrical Cords ................................................................. 96

7.8

Filling the HTF Reservoir .................................................................... 97

7.9

Cleaning the HTF Strainer .................................................................. 98

7.10

Replacing the Fuel Filter .................................................................. 100

7.11

Lubricating the Hose Reel System ................................................... 101

7.12

Storing the Machine ......................................................................... 102

7.13

Preparing the Machine for Seasonal Operation ............................... 103

7.14

Connecting and Maintaining the Battery .......................................... 104

8

Genset Maintenance

106

8.1

Periodic Maintenance Schedule ....................................................... 106

8.2

Checking the Engine Oil ................................................................... 107

8.3

Cleaning the Air Intake ..................................................................... 108

8.4

Servicing the Air Cleaner .................................................................. 109

8.5

Replacing the Fuel Filter .................................................................. 111

8.6

Checking and Adjusting the Valve Clearances ................................ 112

8.7

Changing the Engine Oil .................................................................. 114

8.8

Cleaning the Oil Filter ....................................................................... 115

9

Troubleshooting

117

9.1

Troubleshooting the Machine ........................................................... 117

10 Technical Data

119

10.1

Engine .............................................................................................. 119

10.2

Generator ......................................................................................... 120

10.3

Trailer ............................................................................................... 120

10.4

Machine ............................................................................................ 121

10.5

Dimensions ....................................................................................... 122

MSDS: Dowfrost HD 50

123

Fuji Temperature Controller

130

Tire Safety Information

135

11 Schematics

147

11.1

E 1100 Composite Schematic .......................................................... 147

Summary of Contents for E1100

Page 19: ...E 1100 Safety Information wc_si000628gb fm 19 Notes...

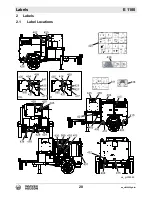

Page 20: ...Labels E 1100 20 wc_si000629gb fm 2 Labels 2 1 Label Locations wc_gr009588...

Page 105: ...ghi_tx001153gb fm 105 E 1100 Maintenance...

Page 122: ...Technical Data E 1100 122 wc_td000476gb fm 10 5 Dimensions cm in wc_gr008706...

Page 133: ...wc_tx001673gb fm 133 Fuji Temperature Controller...

Page 134: ...wc_tx001673gb fm 134 Fuji Temperature Controller...

Page 151: ...E 1100 Schematics wc_tx001908gb fm 151 11 3 Burner System Circuit...

Page 152: ...Schematics E 1100 152 wc_tx001908gb fm 11 4 Circulation System Circuit ghi_gr005662...

Page 153: ...E 1100 Schematics wc_tx001908gb fm 153 11 5 Rewind System Circuit...

Page 158: ...Schematics E 1100 158 wc_tx001908gb fm 11 10 Genset DC Wiring Diagram...

Page 160: ......

Page 161: ......