7-48

BA EZ17 en* 1.1 * ez17w710.fm

7 Maintenance

7.19 Maintenance and care of attachments

Important information regarding maintenance of attachments

Correct maintenance and service is absolutely necessary for smooth and

continuous operation, and for an increased service life of the attachments.

Please observe the lubrication and maintenance instructions in the

Operator’s Manuals of the attachments.

7.20 Maintenance of options

Joint rod (lifting eye) and load hook

Wear of joint rod (lifting eye)

Immediately replace lifting eyes with inadmissible wear (for example if

they are beyond the max. tolerance), damage, deformations, surface

cracks and corrosion.

The nominal size must not be worn more than 5 % (max. tolerance).

Measurement can be performed with the accuracy of a slide gage.

Welding is prohibited!

Load hook wear

Have load hooks (Powertilt, Powertilt for Easylock) with inadmissible wear

(for example beyond the tolerance), damage, deformations, surface

cracks and corrosion immediately replaced by a Wacker Neuson service

center.

The nominal size must not be worn more than 10 % (max. tolerance).

Measurement can be performed with the accuracy of a slide gage.

Welding is prohibited!

If the spring mechanism of snap link

C

does not automatically close any

more, stop machine operation with the load hook and have the error

repaired by a Wacker Neuson service center.

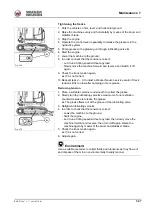

A

B

Fig. 236

Joint rod (lifting eye)

Nominal size A

Max. tolerance B

EZ17

32 mm

(1 1/4 in)

33.6 mm

(1 3/8 in)

Fig. 237 (symbolic representation)

B

A

C

A

Load hook

Nominal

size A

Max. tolerance

A

Nominal

size B

Max. tolerance

B

Nominal

size C

Max. tolerance

C

EZ17

(PTS-4.5)

86 mm

(3 3/8 in)

94.6 mm

(3 3/4 in)

30 mm

(1 1/8 in)

27 mm

(1 in)

33 mm

(1 1/4 in)

36.3 mm

(1 3/8 in)

Summary of Contents for E13-01

Page 6: ...EG 2 BA EZ17 en 1 1 ez17konf fm Declaration of conformity Notes...

Page 36: ...2 22 BA EZ17 en 1 1 Safety_01_0 fm 2 Safety Notes...

Page 45: ...BA EZ17 en 1 1 ez17e300 fm 3 9 Introduction 3 Warning labels...

Page 50: ...3 14 BA EZ17 en 1 1 ez17e300 fm 3 Introduction Labels...

Page 90: ...4 36 BA EZ17 en 1 1 ez17i400 fm 4 Putting into operation Notes...

Page 158: ...5 68 BA EZ17 en 1 1 ez17b510 fm 5 Operation Notes...

Page 216: ...7 50 BA EZ17 en 1 1 ez17w710 fm 7 Maintenance Notes...

Page 220: ...8 4 BA EZ17 en 1 1 ez17b800 fm 8 Malfunctions Notes...

Page 244: ...9 24 BA EZ17 en 1 1 ez17t900 fm 9 Technical data Dimensions Fig 243...

Page 246: ...9 26 BA EZ17 en 1 1 ez17t900 fm 9 Technical data Notes...