5A-11

50 HZ PORTABLE GENERATORS

G3.3A/G4.6A/GS4.6A/GS5.7A

5A

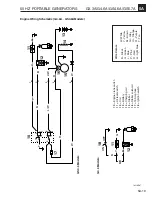

5.15 Rotor Windings

Before testing rotor, visually inspect windings for dark

streaks which indicate a burned or shorted winding.

Rotate ball bearing by hand. Replace it if it is rough, noisy

or dry.

Checking Rotor

1. Remove end cover and brush assembly.

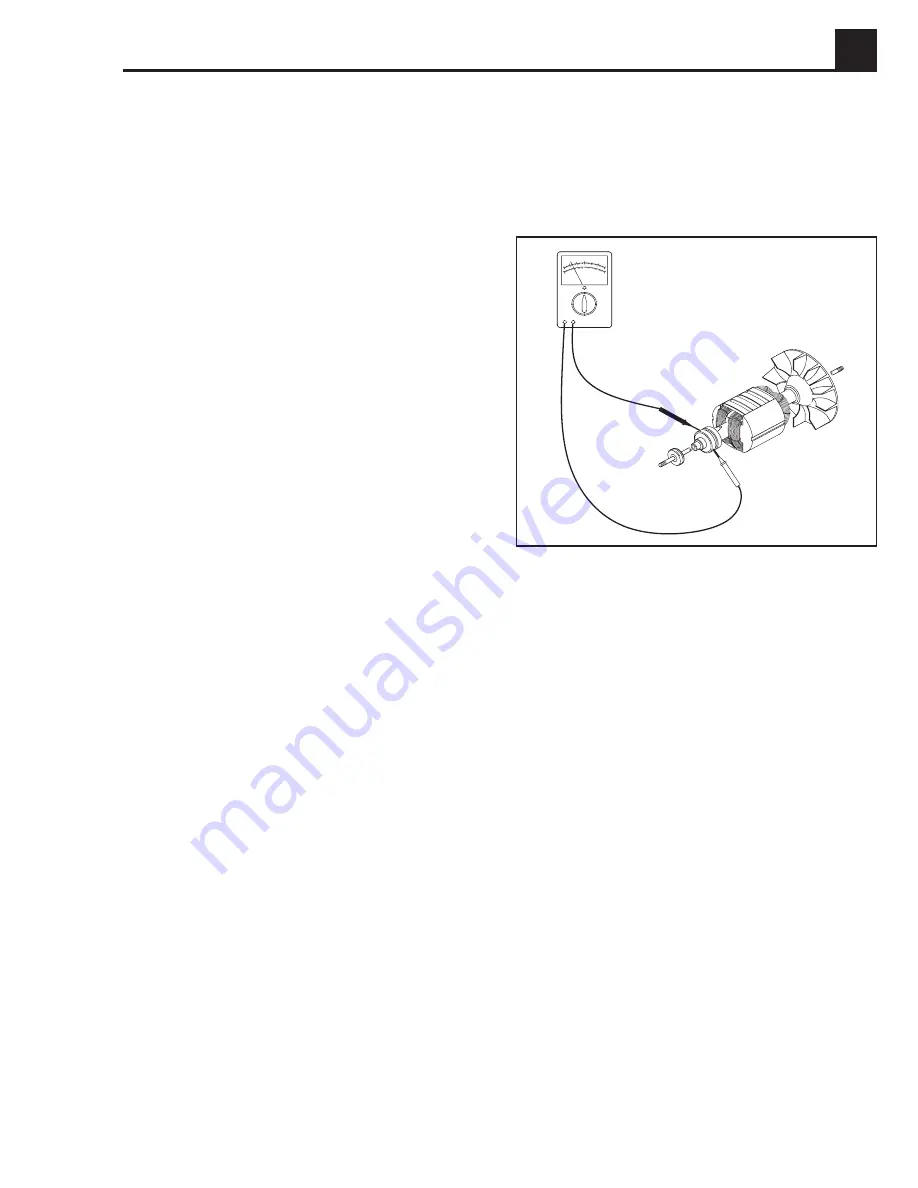

2. Measure resistance as shown in the illustration, by

measuring the winding at the slip rings. See Figure

5-15.

3. Record resistance values of both windings and

compare them with values listed in Table 5-1.

4. Check for grounded windings by holding one meter

lead to winding and other lead to metal frame on rotor.

Replace rotor if windings are open, shorted internally or

shorted to metal frame.

5.16 Slip Rings and Brushes

Slip Rings

Inspect the slip rings for dirt or damage. If the slip rings

are dirty, use an eraser or non-metallic abrasive pad to

clean the rings and then retry the generator.

Brushes

Inspect the brushes for damage, dirt, freedom of

movement, or brush length. Brushes less than 8 mm in

length should be replaced. Also replace damaged

brushes.

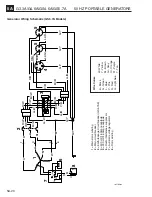

5.17 Automatic Voltage Regulator

To check the regulator:

•

If the generator has low voltage, approximately 2 – 5

VAC as measured at the 120 VAC receptacles,

remove F1 and F2 from the regulator. Start and run

the generator. If voltage output is approximately 150

VAC measured at the receptacles and engine speed

is 3750 rpm, replace regulator.

•

If the generator has low voltage, approximately 65

VAC measured at the 120 VAC receptacles, remove

F1 and F2 from the regulator. Start and run the

generator. If voltage output is approximately 150

VAC measured at the receptacles, and engine speed

is 3750 rpm, replace regulator.

•

If the generator has high voltage, approximately 150

VAC as measured at the 120 VAC receptacles, and

the engine speed is 3750 rpm, replace regulator.

Figure 5-15. Checking Rotor

1024SD02