wc_tx003107gb.fm

95

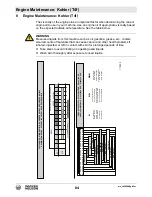

LTN

Schematics

11 Schematics

11.1

LTN 8K-V Lighting Schematic

17 BK 10

2

4

1

3

16 BK 10

23 WH 10

23 WH 10

22 GN/YL 10

22 GN/YL 10

16 BK 10

18 BK 10

19 BK 10

18 BK 10

19 BK 10

3 BK

10

6 BK 14

12 BK 14

14 BK 14

26 WH 10

25 BK

10

24 BK 10

27 GN/YL 10

27 GN/YL 10

8 WH 10

9 WH 10

28 BK 10

29 BK 10

23 WH 10

27 GN/YL 10

22 GN/YL 10

11 GN/YL 12

9 WH 10

8 WH 10

1 BK 10

1 GN/YL 12

12 GN/YL

11 GN/YL 12

1

2

10 WH 10

3

4

2 BK 10

13 BK 10

1 BK 10

4 BK 10

7 BK 10

6 BK 10

2

GN

WH

GN

BL

4

PU

WH

BL

WH

BL

11 GN/YL 12

10 WH 10

4

BK

RD

GN

WH

GN

BL

1

WH

OR

BR

3

BL

YL

GN

2

YL

YL

BK/YL

1

YL

YL

3

BK/YL

BK/YL

PU

YL

YL

WH

8 WH 10

YL

BK/YL

YL

9 WH 10

OR

BR

7 BK 10

6 BK 10

5 BK

10

d1

d3

s3

b

o

eg

eg

ff

c

f

t

v

a

b

s1

s2

s4

m

h

mm

m

d2

d4

wc_gr010838