3 Safety

16

Operator's manual

Storage location

After operation, allow the machine to cool and then store it in a sealed-off, clean

and dry location protected against frost and inaccessible to children.

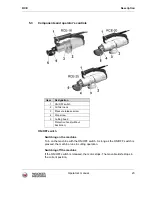

3.6

Safety during the operation of hand machines

Safe working with hand machines

Secure loose workpieces with suitable methods.

While working, as a rule hold the machine on the provided handles with both

hands.

3.7

Safety during the operation of electric appliances

Specific regulations for electrical appliances

Observe the safety information provided in the brochure

General Safety Rules

which is included in the scope of delivery of your machine.

Also observe the country-specific regulations, standards and guidelines in refer-

ence to accident prevention in connection with electrical equipment and ma-

chines.

WARNING Read all safety information and instructions.

Failure to follow

the safety information and instructions may result in electric shock, fire and/or se-

rious injury.

Save all safety information and instructions for future reference.

Summary of Contents for RCE

Page 1: ...Operator s manual Cutting machine RCE 0215051en 003 12 2009 ...

Page 50: ...Technical data RCE 50 Operator s manual ...

Page 54: ......

Page 55: ......

Page 56: ......