RCP

Troubleshooting

41

9

Troubleshooting

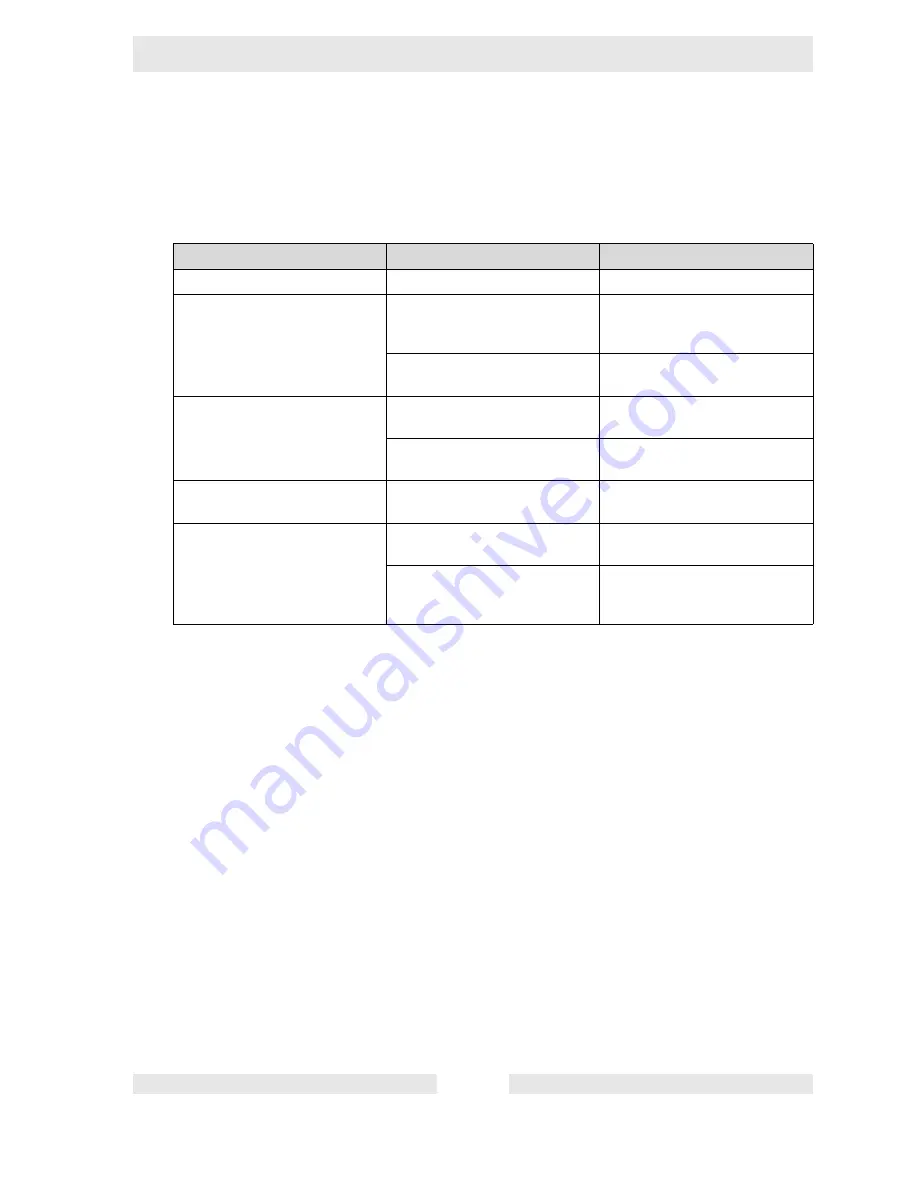

Potential faults, their causes and the respective remedies are listed in the follow-

ing table.

Notify your WACKER contact in case of malfunctions you cannot or may not rem-

edy yourself.

Malfunction

Cause

Remedy

Workpiece jammed or slipped.

Stop screw is set incorrectly.

Adjust the stop screw.

Machine not in operation.

Input voltage too high or too

low.

Provide correct voltage; if nec-

essary use an extension cable

with sufficient cross section.

Power cable interrupted.

Check power cable, have it re-

placed if defective.

Thrust bolt moves out incom-

pletely or unevenly.

Insufficient hydraulic oil in the

hydraulic oil tank.

Check oil level, fill with hydrau-

lic oil if necessary.

Cold hydraulic oil.

Warm up machine for approx.

1 minute.

Thrust bolt does not move back

completely.

Dirt and cutting residue in the

cutting head.

Clean cutting head.

Hydraulic oil is leaking out.

Sealing ring on the oil filler neck

is damaged.

Check sealing ring, change if

necessary.

Leak on the hydraulic cylinder,

hydraulic oil tank or screwed

connections.

Have the machine repaired.

Summary of Contents for RCP 20

Page 1: ...Operator s manual Cutting machine with interchangeable head RCP 20 25 0215052en 002 03 2008...

Page 2: ......

Page 58: ......

Page 61: ......

Page 62: ......