INTERCEPTORS

5

Wade

Drains

‐

11910

CR492,

Tyler,

TX,

75706

‐

Phone:

800

‐

638

‐

9537

Fax:

888

‐

879

‐

9233

‐

www.wadedrains.com

3

‐

29

‐

17

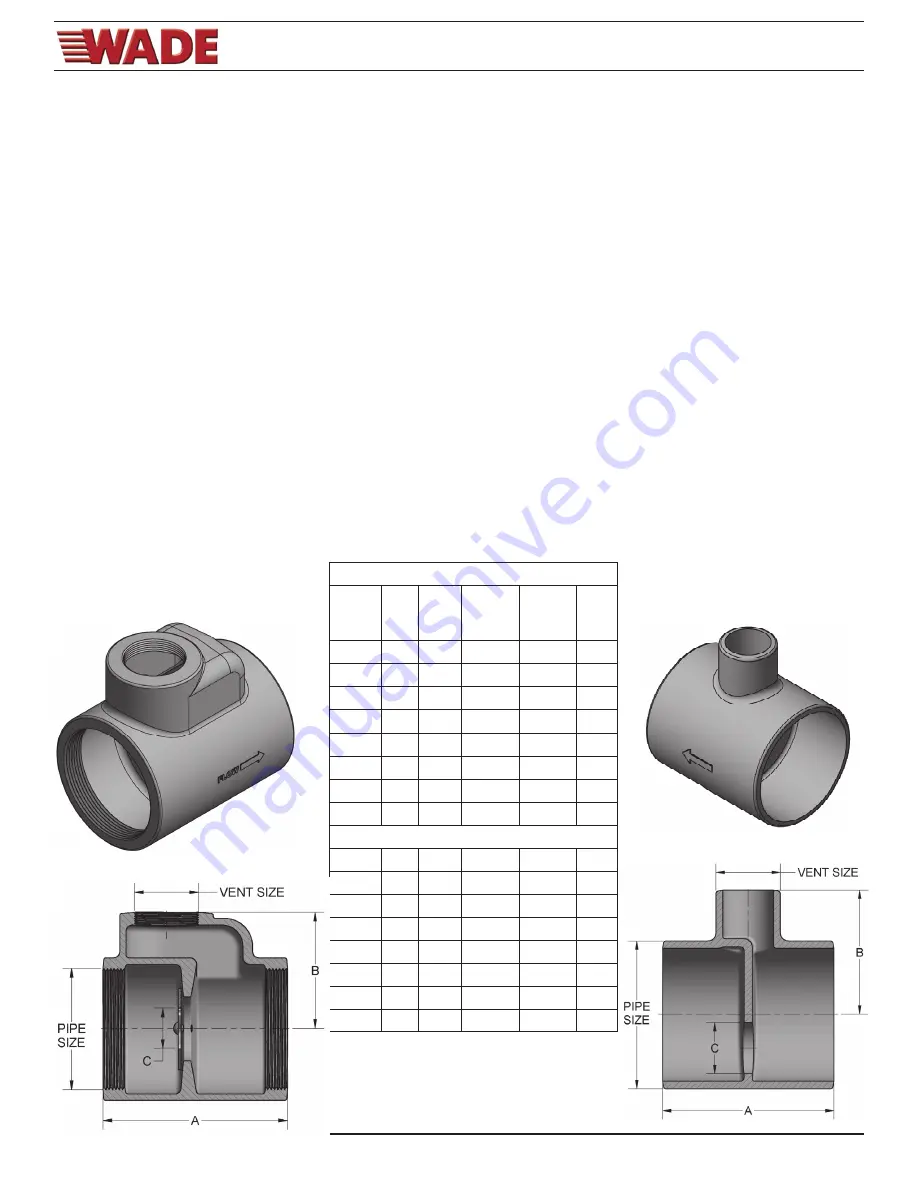

FLOW CONTROL

The flow control device is designed with an integral orifice to achieve a predetermined optimum flow rate, thus

eliminating turbulence and to regulate surges in the drainage line. The orifice opening in the flow control device is related

to the size and flow rating of the grease interceptor. The standard orifice sizes are for gravity flow conditions where no

pressure buildup is anticipated. If an interceptor is operating at maximum flow levels, a pressure head may develop,

which may cause an overload condition.

Using the supplied flow control device is an important factor in the operation of the grease interceptor. The flow control

device must be installed in the waste line upstream of the grease interceptor. Typically, the device is placed beyond the

last connection from the fixture(s) and as close as possible to the underside of the lowest fixture. When two or more

sinks or fixtures are combined and served by a single interceptor, a single flow control may be used.

The supplied flow control device must be properly vented to permit air to mix with the fluid entering the interceptor. Air

facilitates the separation and, more Importantly, is necessary to maintain optimum pressure, thereby maintaining the

proper operating level within the interceptor chamber.

The flow control air intake may terminate under the sink drain board as high as possible, to prevent overflow. Another

method is to terminate the vent outside the building. It is recommended that the installer check with the local plumbing

code authority.

VENTING

Grease interceptors must have a vented waste, sized in accordance with code requirements for venting traps, to retain a

water seal and to prevent siphoning.

Flow

Rate

Pipe

Size

Vent

Size

A B

C

4

2”

1 1/4” 3 15/16” 2 11/16” .500

7

2”

1 1/4” 3 15/16” 2 11/16” .688

10

2”

1 1/4” 3 15/16” 2 11/16” .844

15

2”

1 1/4” 3 15/16” 2 11/16” 1.000

20

3”

1 1/2” 5 5/16”

3 11/32” 1.156

25

3”

1 1/2” 5 5/16”

3 11/32” 1.313

35

4”

2”

6 11/16” 4 11/32” 1.500

50

4”

2”

6 11/16” 4 11/32” 1.875

FC-NH

4

2”

1 1/2” 5 1/16”

2 1/2”

.500

7

2”

1 1/2” 5 1/16”

2 1/2”

.688

10

2”

1 1/2” 5 1/16”

2 1/2”

.844

15

2”

1 1/2” 5 1/16”

2 1/2”

1.000

20

3”

1 1/2” 5 1/16”

3 1/4”

1.156

25

3”

1 1/2” 5 1/16”

3 1/4”

1.313

35

4”

1 1/2” 5 1/16”

3 11/16” 1.500

50

4”

1 1/2” 5 1/16”

3 11/16” 1.875

FC-IPS