INTERCEPTORS

8

Wade

Drains

‐

11910

CR492,

Tyler,

TX,

75706

‐

Phone:

800

‐

638

‐

9537

Fax:

888

‐

879

‐

9233

‐

www.wadedrains.com

3

‐

29

‐

17

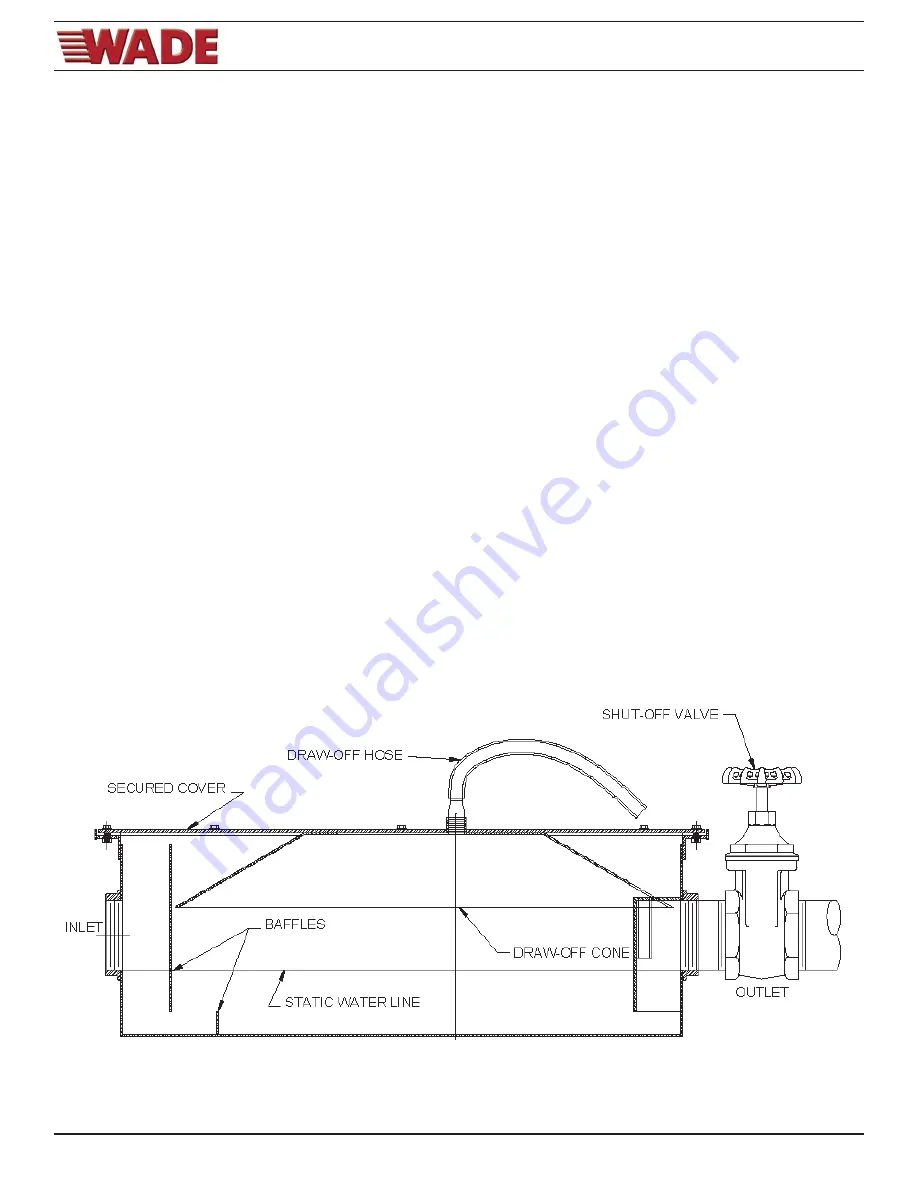

Cleaning (5103 Series) Semi-Automatic Interceptor

To assist in the maintenance and cleaning process, Wade offers a unit incorporating a top draw-off port for grease

removal. The cover has an accumulating hood to capture the liquid grease and funnel into the draw off port. Cleaning

can easily be performed by following the steps listed:

1. The interceptor in normal use has the control valve off and the drain port plugged. When cleaning is required, run a

full stream of hot water through a fixture serviced by the interceptor. This will liquefy the grease for extraction. A

period of two minutes is required.

2. With the hot water supply shut off, turn the in-line closure valve to a fully closed position.

3. Remove the bronze plug from the cover and insert the hose fitting and flexible draw off hose, tightening the hose

fitting securely. Place the end of the hose into a container suitable for disposal.

4. Turn the hot water supply back on back on and allow the water pressure to steadily force the liquefied grease

through the hose. Caution: The liquid grease may be hot when exiting the draw-off hose; take care to keep the water

flow as laminar as possible to prevent grease spilling.

5. Once grease is no longer visible at the discharge end, turn the water supply off. Properly dispose of the grease.

Never dispose of the contents in any part of the plumbing system.

6. Remove the draw-off hose and fitting and replace the bronze plug.

7. Fully open the in-line control valve.

8. Periodic inspections of the flow control orifice are suggested.

9. A bi-annual inspection of the internals of the interceptor is recommended. Inspect and clean the baffle assembly and

thourghly clean the body of all solids and debris.