INTERCEPTORS

9

Wade

Drains

‐

11910

CR492,

Tyler,

TX,

75706

‐

Phone:

800

‐

638

‐

9537

Fax:

888

‐

879

‐

9233

‐

www.wadedrains.com

3

‐

29

‐

17

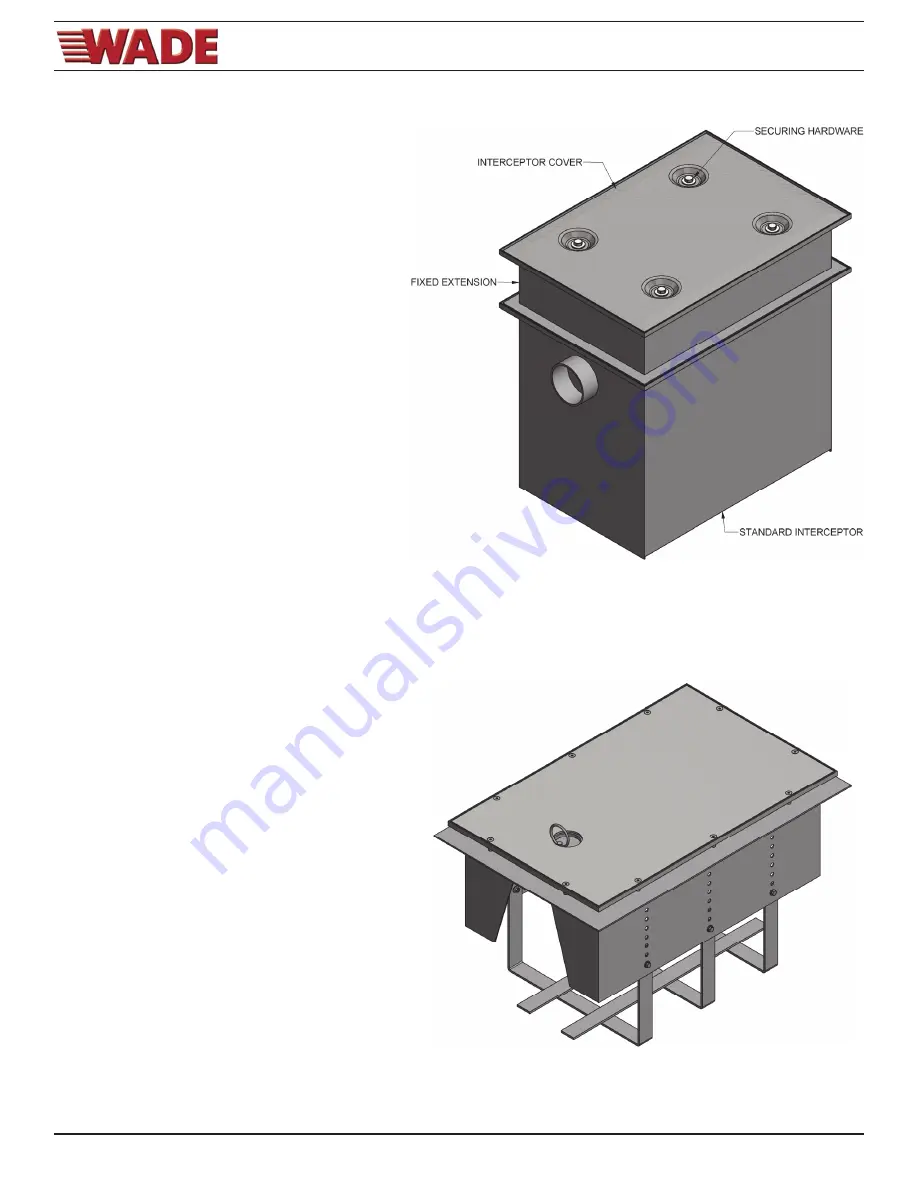

EXTENSIONS (Bolt-On & Integral)

Extensions should be specified on grease and oil

interceptors when the interceptor is buried in the ground,

vertical adjustment of the interceptor is necessary to

meet the drainage piping, and/or floor level access

requirements. Extension heights range from four inches

to any maximum practical for serviceability. Extensions in

excess of 20" are not recommended. One must consider

the slope of the drainage piping from the fixtures to the

inlet of the interceptor. Typically, allow a slope of ¼" per

foot in the drainage pipe. Therefore, there will be many

installations, especially with large interceptors, where

the sloped drainage pipe ends up below the inlet

connection. An extension is added to the top of the

interceptor so that the inlet can be lowered to meet the

incoming drainage pipe and the lid of the interceptor can

be extended to floor level.

Wade offers three different kinds of extensions: integral,

bolt on and cover shrouds. An integral extension is

specified by expanding the "H" dimension on the

interceptor. The "H" dimension is from the center of the

inlet and outlet to the top of the interceptor. One would

specify a "H" dimension to meet the job requirements

and the interceptor will be manufactured to that

specification. The extension is incorporated into the

production of the interceptor to produce a seamless,

integral interceptor.

A second method of providing an extension is a bolt on

design. In this example, a top is manufactured out of the

same material as the body. The extension is secured to

the body by means of bolts bearing against its base

flange, compressing the sealing gasket to complete the

union. The regular lid is bolted to the extension top in the

same manner as it would be to the body of a standard

interceptor.

SHROUDS

Cover shrouds incorporate either standard or draw-off

grease interceptors mounted on adjustable elevation

cradles in either open or closed bottom housings with

non-skid floor level lids. The cover shroud is adjustable

and is recessed into the slab to house the interceptor.

Cover shrouds are particularly important where below

floor level installation of draw-off grease interceptors is

required, because such models cannot be installed

independently with tops at the finished floor level.