EN

117

AirConServiceCenter

Troubleshooting

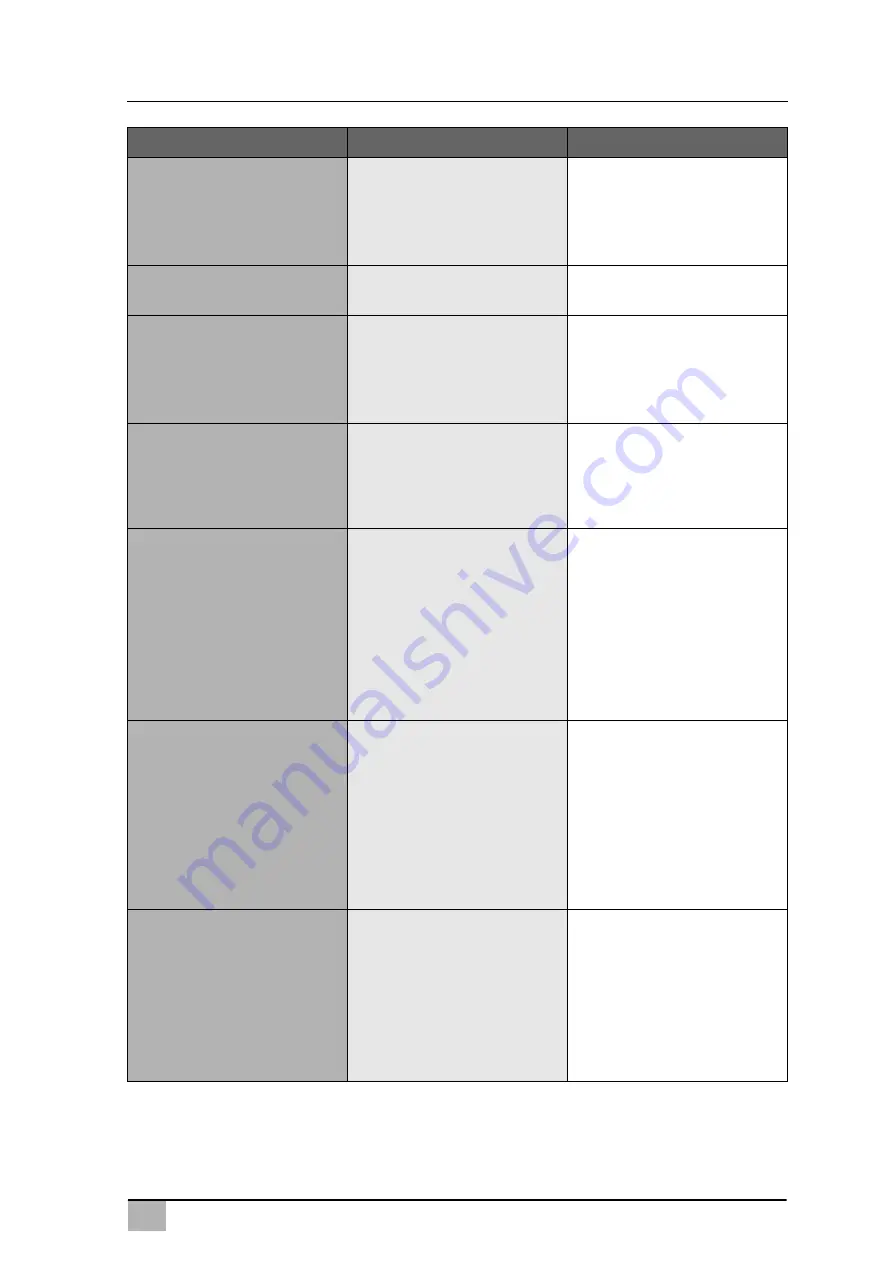

The display shows

“

Error 02”

Pressure increased again

with pressure increase test. It

is not possible to reduce

pressure sufficiently.

Check air conditioner and

connections for leaks, con-

strictions and ice build-up.

Check pressure transducer

calibration.

The display shows

“Error 03”

No data is coming from the

refrigerant scale.

Check the scale.

The display shows

“Error 04”

It is not possible to lower the

pressure when flushing takes

place.

Check air conditioner and

connections for leaks, con-

strictions and ice build-up.

Check pressure transducer

calibration.

The display shows

“Error 09”

During the flushing process,

no pressure could be ascer-

tained at the low pressure

connection of the air condi-

tioning service unit.

Connect low pressure hose

to the flush container and

open valve.

The display shows

“Error 10”

During the software test, the

compressor failed to reduce

the internal pressure suffi-

ciently.

Residual pressure on the

pressure gauges?

Check pressure transducer

calibration.

Check internal bottle pres-

sure.

Check the compressor and

the corresponding solenoid

valves.

The display shows

“Error 11”

It was not possible to drain

any used oil during the soft-

ware test.

Is there residual oil in the dis-

tillator, or was the draining of

used oil interrupted during

the last process?

Insert bottle for used oil cor-

rectly.

Is there a vent hole in the

used oil container/is the vent

hole clogged?

The display shows

“Error 12”

It was not possible to remove

any refrigerant from the inter-

nal tank during the software

test.

Check pressure transducer

calibration.

Check whether the tank

valve on the internal tank is

open.

Check the RE valve.

Is the ambient temperature

below 10 °C?

Problem

Cause

Remedy

Summary of Contents for AirConServiceCenter ASC1000G

Page 2: ......