EN-RATIOfresh-250-400_TI-MA-0809-11214900

11

3.7 Switching the Primary Return Flow

(fig. 15)

When the RATIOfresh freshwater unit is used in systems

that are continuously operated at water temperatures >=

60 °C and work with circulation nets, we recommend the

controlled switching of the return flow to the buffer cylin-

der. Thus it can be avoided that during periods of low hot

water drawing, hot water enters the lower part of the the

buffer cylinder where it could cause unwanted mixing.

The switching can be carried out by a 3-way valve (see solu-

tion shown in fig. 15). The valve should have short switching

times (<30 s) and low pressure loss. (e.g. Wagner & Co 3-

way-valve, order no. 160 101 44). Control should be based

upon temperature difference, e.g. via solar controller

SUNGO SXL.

3.8 Connecting the Controller (fig. 9)

All tasks and activities involving the transport, installation,

as well as operation and servicing must be performed by

qualified technical personnel.

The controller is for the most part prewired. A fourth tem-

perature sensor and a circulation pump can be connected

in addition to the mains connection. If the disinfection func-

tion is utilized, the auxiliary heating of the buffer cylinder

must be activated via the external switching output.

●

To open the controller turn the 4 Phillips screws (cf. 10-9)

to the left by 90° and remove cover of housing. Remove

the flat ribbon cable plug to the display board from

socket

(3)

and set aside the cover of the controller to

avoid damaging it.

●

Remove the plug

(4)

to the mains connection from

socket

(5)

, route the mains cable (cable cross-section 3 x

0.75 to 1.5), e.g. along the primary return and a free PG

gland (cf. 10 no. 10), into the station. Attach phase, zero

conductor, and potential ground to plug

(4)

and then in-

sert this plug into socket

(5)

.

●

If needed, connect the circulation pump with plug

(6)

in

the same way and plug into socket

(7)

(required cable

cross-section: 3 x 0.75 to 1.5).

●

A fourth temperature sensor (type KTY, cf. accessories)

can be connected via plug

(8)

and socket

(9)

.

●

A RS 232 interface cable available as an accessory can

be connected to plug

(12)

(socket

(13)

). It is also possi-

ble to log all measured values, the current controller sta-

tus, and the current pump output. This requires connect-

ing the 9-pin D-SUB plug of the data cable to the serial

RS 232 interface of a computer. Possible logging utilities

are a terminal program such as included with Windows

95, 2000, or XP (All Programs -> Accessories). Use these

transfer settings: RS 232 Port = COM1/COM2, Emula-

tion = ANSI, Transfer rate = 19200 bit/s, Data bits = 8,

Stop bits = 1, Parity = None, Protocol = No protocol

(XON/XOFF, RTS/CTS).

●

The additional external switching output of the

RATIOfresh freshwater station on plug

(14)

socket

(15)

is

intended for the activation of the aux. boiler heating for

the disinfection operation. Please note that the current

applied to this potential-free switching contact may not

exceed a current intensity of max. 0.5 A. If a boiler de-

mand is triggered, the controller closes contact 11-12

and opens contact 11-13. Once the boiler is no longer

needed, contact 11-12 is opened again and contact 11-

13 is closed again. If contact 11-12 is closed, the third

LED from the left (cf. 10-3) is continuously green.

●

fig. 9 also depicts the control fuse

(16)

(400mAT / 250 V)

and the output fuse

(17)

(6.3 AT / 250 V).

●

Hold controller housing cover before the bottom sec-

tion of the housing, reattach the flat ribbon cable to the

display board

(3)

, attach the cover to the bottom section,

press down the 4 Phillips screws (cf. 10-9) and turn to-

wards the right by 90°.

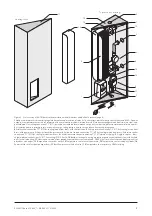

3.9 Closing the Housing (fig. 8)

To close the metal housing, insert the housing cover

(1)

into

the snap-in groove

(2)

at the bottom section of the housing

(3)

and then snap the two snap-in plugs

(4)

at the bottom

into sockets

(5)

.

2

1

4

3

4

5

5

Figure 8 Close housing

1

Housing cover;

2

Snap-in groove;

3

Bottom section of housing;

4

Snap-in plug;

5

Snap-in socket.