22

EN-RATIOfresh-250-400_TI-MA-0809-11214900

7. Maintenance and Care

The system should be checked annually:

●

Check all screw connections and soldered points for

leaks.

●

In case of potable water with an increased carbonate

content, the heat exchanger should be checked regu-

larly for lime buildup. The following changes are indica-

tive of lime buildup: Return temperatures of the primary

circuit are significantly above those listed in Table 14. The

max. hot water volume flow that can be withdrawn has

been reduced. The set nominal hot water temperature is

no longer reached with frequent water withdrawals.

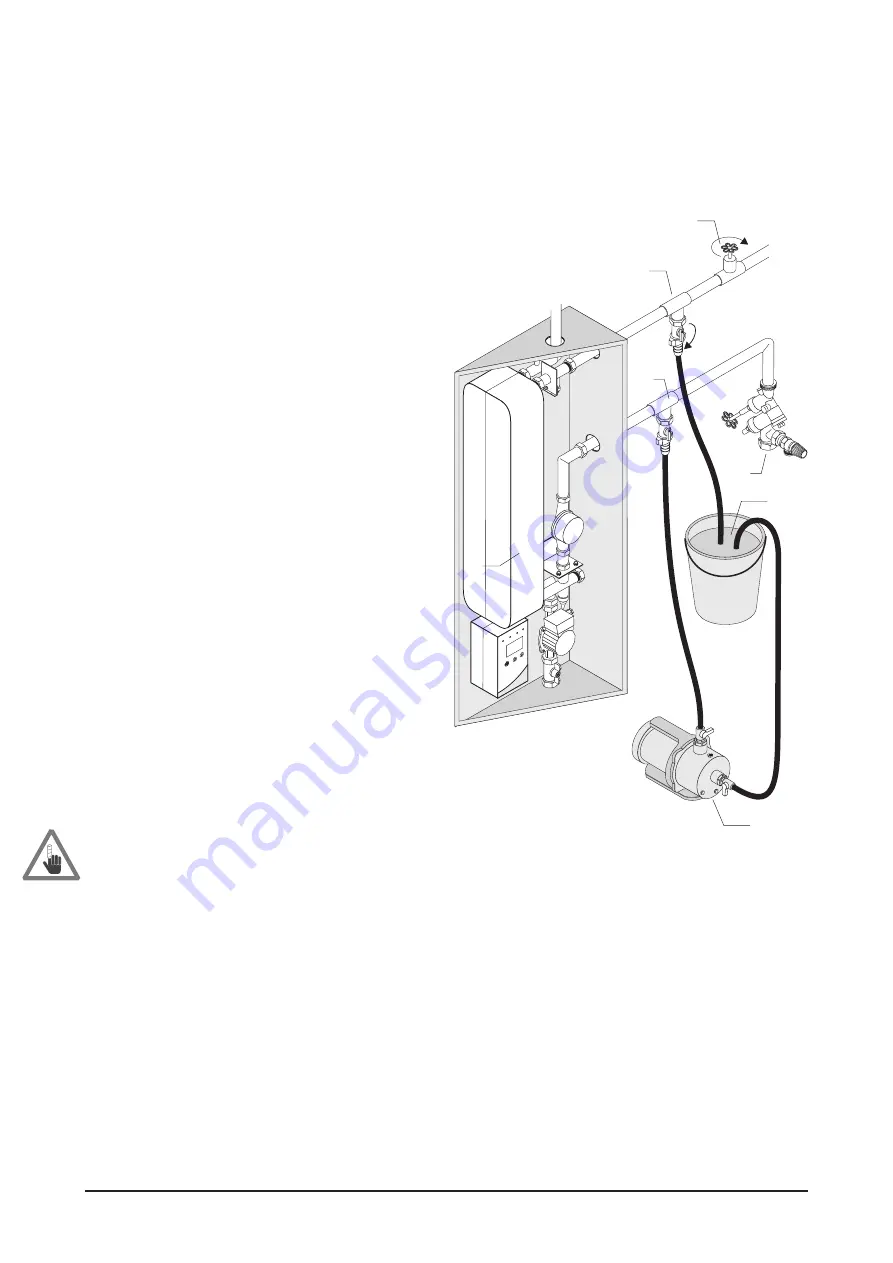

Decalcification of the Heat Exchanger (fig. 6, 11, 12)

If flushing spigots are installed in the cold and hot water

lines, the heat exchanger can be decalcified by flushing the

system (fig. 11). If flushing spigots are not in place, the en-

tire heat exchanger must be removed from the station (fig.

11. This requires the following:

●

De-energize the station!

●

Depressurize the potable water line by closing the shut-

off valves at the safety subassembly

(fig. 6, no. 3)

and in

the hot water network

(fig. 6, no. 11)

. Empty the potable

water side of the heat exchanger using the drain spigot

(fig. 6, no. 9)

installed in the cold water supply line.

●

Close shut-off valve

(fig. 11, no. 5)

in the primary circuit

flow and pump slider

(fig. 11, no. 7)

to block primary cir-

cuit

(fig. 11, no. 2, 9)

.

●

Empty heat exchanger

(fig. 11, no. 3)

on the primary side

by loosening the 1" bolt

(fig. 11, no. 6)

at the primary

flow connection and

(fig. 11, no. 10)

at the primary re-

turn.

●

To remove the heat exchanger, remove all four 1" swivel

nuts

(fig. 11, no. 4, 6, 10, 11)

using a size 36 wrench.

Place heat exchanger over night into a commercially

available decalcification solution or a 5 % vinegar solu-

tion followed by a thorough cleaning. Be careful when

handling decalcification and vinegar solutions!

●

To flush the heat exchanger (fig. 12), pump the cleaning

fluid

(fig. 12, no. 1)

through the circuit‘s heat exchanger

(fig. 12, no. 13)

and the filling spigot

(fig. 12, no. 10)

with

a feed pump

(fig. 12, no. 2)

using the filling spigot

(fig.

12, no. 9)

and then neutralize it according to the instruc-

tions of the manufacturer of the cleaning fluid.

Only use cleaning fluids approved for potable water and

perform the neutralization according to the instructions!

Be careful when handling any chemical solutions!

●

After reinstalling the heat exchanger or completing the

flushing process, open all shut-off valves and spigots,

apply voltage to the controller, and vent the primary cir-

cuit according to Chapter 5 Initial Startup.

90°

90°

10

9

11

3

1

13

2

Figure 12 Heat exchanger decalcification

1

Cleaning fluid;

2

Feed pump;

3

Safety subassembly;

9

Filling spigot;

10

Filling spigot;

11

Ball valve;

13

Heat exchanger.