EN-USA_SECUSOL_TI-MA-111013-1121R800

25

33

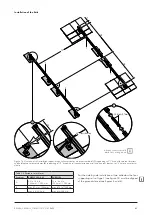

2

1

M8 x 40

12.5 lb-ft (17 Nm)

12.5 lb-ft (17 Nm)

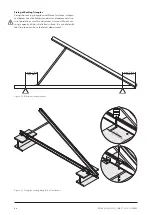

Figure 21 Unfold racking triangle, set correct angle and lock in position

Installation of Racking Triangles

Use appropriate wrench, e.g. combined

wrench 13 mm / 1/2 inch, such as Met-

rinch MET-1113, or adjustable spanner.