EN-USA_SECUSOL_TI-MA-111013-1121R800

29

3.4 General Notes about Storage

Installation

The pre-assembled return flow sub-assembly has a 12

mm pipe nozzle on the solar circuit side (

➊

) --> Numbers

in black circles refer to Figure 26.

3.5 Setting up the Storage Tank

Please observe the following when setting up the storage

tank (Figure 8 page9):

The tank insulation consists of 3 parts, the tank insulation

(1), the cover insulation (2) and the pre-installed ground

insulation (3).

●

Remove the tank insulation, the storage cylinder lid (4)

as well as the cover insulation and put safely aside.

●

Unscrew cylinder (6) from the pallet and carry to its final

position. Note that the enamel coating of the storage

tank can be damaged if jolted.

●

Remove 1“ NPSM plug (10) from the pallet and put

aside.

●

Place the storage cylinder so that the connections will

face the wall.

●

During transport a cable binder is used to secure the

pre-wired controller at the cylinders hoisting lug. Cyl-

inder temperature sensor and pump control cable also

are pre-wired.

3.6 Connection to Domestic Water

Supply

Hot and Cold Domestic Water

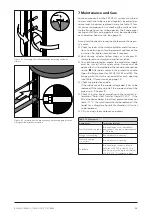

Cold and hot water connections must be done according

to the rules and regulations of your local water supplier.

We recommend the connection as shown in Figure 26

●

Connect a safety subassembly (2) with a safety valve

and a non-return valve according to DIN 1988 to the

cold water inlet of the tank (

➋

).

Within the United States

the installation of an IAPMO compliant backflow pre-

venter is mandatory for all installations connected to

the drinking water supply.

Risk of serious scalding for the end user!

Water temperatures at hot water taps can reach up to

203 °F / 95 °C!

A thermostatic mixing valve must be installed to avoid in-

juries to end customers!

●

It is absolutely necessary to install a thermostatic mix-

ing valve (3) since temperatures during the summer

months can reach up to 203 °F / 95 °C at the hot water

outlet.

➐

Without thermostatic mixing valve there is a

considerable risk of scalding. The thermostatic mixing

valve can be connected between safety subassembly

(2) and the cold water connection at the storage tank

➋

using a T-piece.

●

Close the 1" NPSM socket

➍

with the plug and seal

thoroughly. Alternatively an electrical immersion heat-

er is available which can be installed in this socket, as

outlined in the chapter “Backup Heating”.

●

Re-tighten bolts around flange cover (6) to ensure leak-

age-free operation.

Re-Circulation

The return leg (8) should be led away just before the tap-

ping point (10). The circulation pump (9) should be cont-

rolled according to the hot water temperature at the most

distant tap (sensor 11). We recommend that the circula-

tion should be returned to the cold water inlet (4) of the

thermostatic mixer (3). A check valve should be installed

in the circulation pipe. Please note that circulation can

cause significant loss of heat. Hint: use a time, tempera-

ture or tap-event controlled circulator.