EN-USA_SECUSOL_TI-MA-111013-1121R800

37

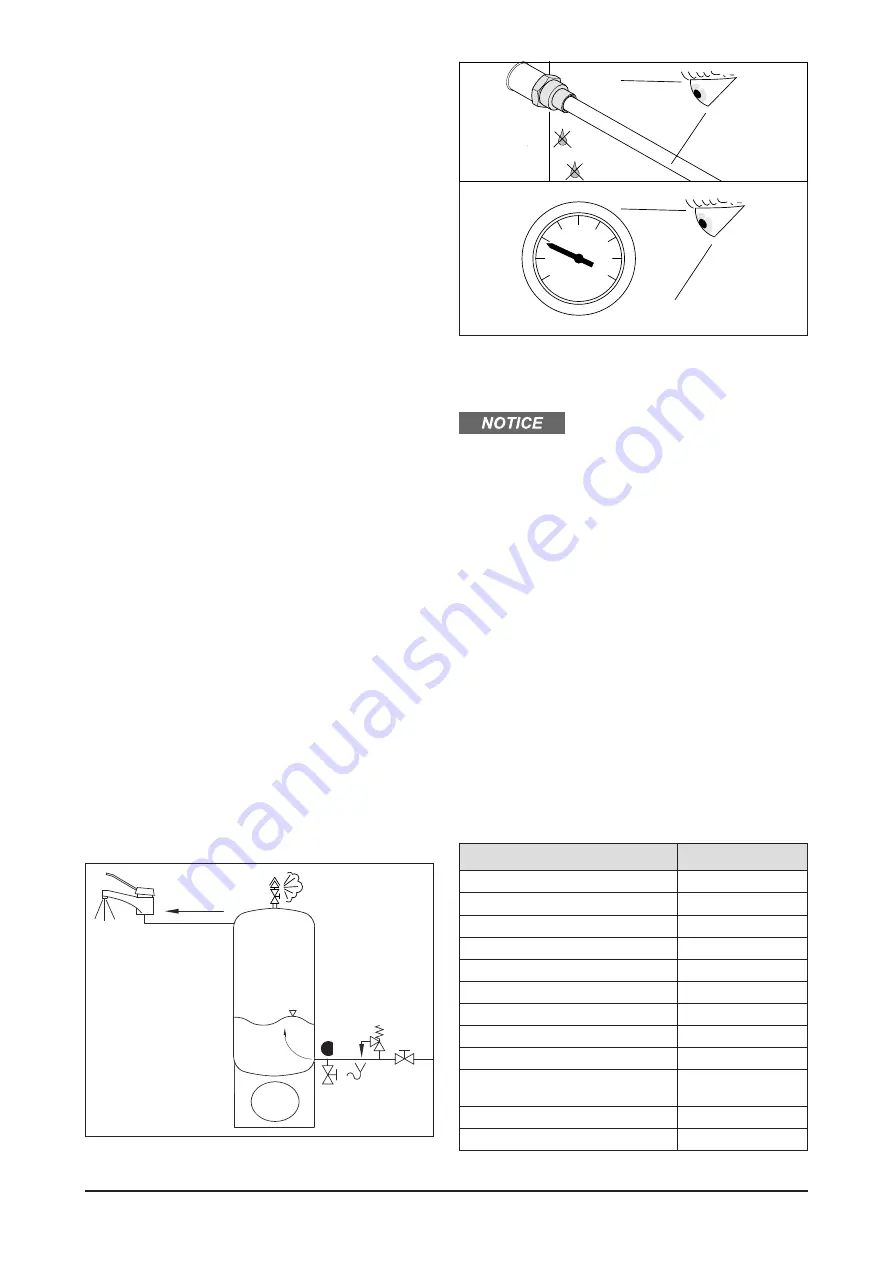

Figure 37 Filling and venting of the storage cylinder

Figure 38 Check connections for tightness, re-tighten if required;

monitor system pressure

bar

is rinsed. Continue the rinsing process until the flow-

ing out liquid is clear, i.e. does not contain any visible

residues.

●

If the collector loop pipes were soldered, the collector

loop also must be rinsed prior to connecting it to the

storage tank. After rinsing, some unwanted domestic

water residues may remain in the system. Therefore

blow forcefully into the end of the hose mounted on

the flow sub assembly to empty the collector loop pipe.

To avoid corrosion, the system must be filled with frost

resistant solar fluid immediately after rinsing.

Filling the Solar Circuit

To protect the system against frost damage, only use the

solar fluid included in the delivery. Follow the steps men-

tioned below to fill the system (Figure 40):

●

Observe the included technical information and mate-

rial safety advice “Solar Heat Transfer Liquid DC 20 F”.

●

Remove canister with DC 20 F (7) from the box and

empty the content (2.5 liters) into a container (6) with a

minimum capacity of 10 liters. Add one full canister (5 li-

ters) of water and stir. The solar liquid mix contains 33%

Glycol guaranteeing frost protection to 1.4 °F / -17 °C.

●

Connect hose (2) with a ½" swivel nut to the cold water

filling and emptying tap at the bottom (3). Place the

other end of the hose into the container (6). Place the

container in a higher position than the solar inlet con-

nection (5). A transparent hose is useful to monitor the

filling level.

●

Connect the second hose (4) to the flow connector

and briefly suck on the hose end. Place the end in the

empty canister (7) and place it on the floor. The solar

liquid automatically siphons into the heat exchanger.

●

After the heat exchanger is filled completely and solar

fluid flows into the hose (4), the two filling taps on the

solar return (3) and the solar flow (5) must be closed.

Setting up the controller

For the operation of the SECUSOL system, special settings

at the controller are required. Please observe the separate

controller manual "SUNGO US plus“.

Switch on the SUNGO US plus controller. The default sys-

tem is the system 1, but the systems 2, 3 and 8, which

are also preset with the value of the Secusol drainback-

system, can be selected as well.

2

The systems 4, 5, 6, 7, 9 and 10 should not be selected

because they are not compatible with the Secusol-system.

Controller Operation:

When the temperature difference between collector

and storage tank bottom is continuously higher than the

switch-on temperature (DT O) for 30 seconds or more,

the controller output R1 switches the pump fully on for a

defined filling time (tFLL). After the filling time the switch-

off conditions will be ignored for a stabilization intervall

of 1 minute (tSTB), in order to avoid a premature system

shutdown, before the controller automatically switches to

normal operating mode. The pump speed varies within

the defined speed interval (nMN: 30% and nMX: 50%) ac-

cording to the collector and tank temperature. The cont-

roller output R1 switches off the solar pump if the tempe-

rature difference between the collector and the storage

tank falls below the specified switch-off temperature dif-

ference (DT F) or if the maximum store temperature (S MX)

is reached.

We recommend the specific SECUSOL settings for the so-

lar circulation pump and the controller acc. to Table 14.

Table 14 Controller settings

value

Switch-on temperature difference (DTO)

25.0 °Ra [12.5 K]

Switch-off temperature difference (DTF)

6.0 °Ra [3.0 K]

Nominal temperature difference (DTS)

30.0 °Ra [15.0 K]

Rise control (RIS)

10 °Ra [5 K]

Minimum speed pump (nMN)

30%

Maximum speed pump (nMX)

50%

Maximum tank temperature (SMX)

180 °F [82 °C]

Emergency temperature, collector (EM)

275 °F [135 °C]

Drainback option (ODB)

On

ODB switch-on condition time period

(tDTO)

30s

ODB filling time t(FLL)

2mn

ODB stabilization time (tSTB)

1mn