38

EN-USA_SECUSOL_TI-MA-111013-1121R800

Starting the System

If the solar heat is sufficient, the controller switches to

the start phase when the switch-on difference is reached.

Keep an eye on the collector temperature. If the collector

loop is filled successfully, the collector temperature chan-

ges. Flow noises in the solar circuit inlet indicate that the

filling process was successful. If after the startup time no

flowing sounds can be heard in the collector loop/flow

sub assembly, increase the start-up phase (time parame-

ter “t1”) on the controller or set the pump speed to a high-

er level.

5 Connecting the storage Insulation

●

When installed or otherwise handled, the insulation

jacket should not be colder than 60 °F / 15°C, in order

to avoid material or optical damage.

●

Close jacket insulation using the hook closure

( Figure 41). First hook into the looses position and

then successively tighten. Apply extra pressure around

the pipe connections. Completely insert cover lid in-

sulation on top, and then attack lid on top and turn, so

that the cutout is placed directly above the controller

(fig.Figure 35 page35).

●

The large round openings in the bottom area of the

insulation are required to cool the circulation pump.

The must not be closed or otherwise blocked during

operation!

●

Insulate the pipes and insert the insulation as deep as

possible into the cutouts of the hook closure aound

the pipe connections in order to minimize heat loss.

( Figure 42). The properties of the pipe insulation have

to be as specified.

1

2

3

4

5

6

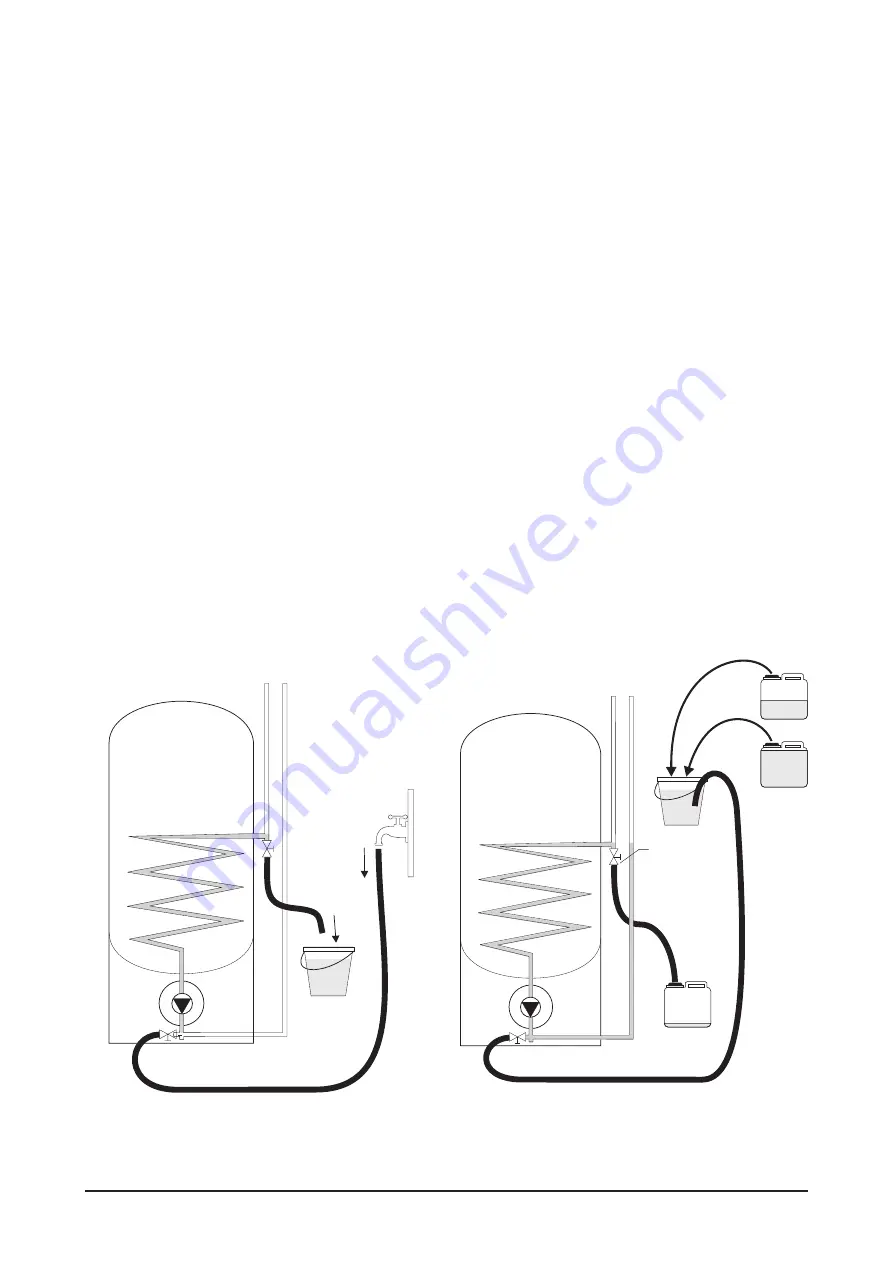

Figure 39 Rinsing the solar installation.

1

Domestic cold water

connection;

2

and

4

Hose;

3

and

5

Cold water filling cock;

6

Con-

tainer.

6 Advice for the User

During normal operation no further settings are required.

Please note the following points:

●

Set hot water temperature

You can pre-set the desired hot water temperature on

the backup heating device. If a thermostatic mixing

valve is installed, it can be used to set the hot water

temperature.

●

Energy efficient operation

Keep the pump level as well as the minimum speed

dn

MIN

as low as possible. The backup heating tempera-

ture of the electrical immersion heater, the installed

continuous flow heater or the heating device should be

set as low as possible. Normally 104 °F to 122 °F (40 °C

to 50 °C) max. is sufficient.

●

Troubleshooting

Please contact expert personnel if the system displays

faults or defects!

●

Operation under frost conditions

The special Drain-Back technology and the use of solar

fluid guarantee protection against frost damage to at

least up to 1.4 °F (-17°C). Therefore the solar energy

system can also be operated in winter.

●

Protection against overheating

The solar energy system is absolutely safe during stag-

nation. There is no risk of damage, even if the sun

shines for longer periods without hot water being

tapped. The system switches on automatically as soon

as the solar cylinder is ready to take in more heat.

●

Shutting down the system

The system can be temporarily shut down by switching

off the electric power supply to the solar controller.The

system should be inspected (see following chapter 7).

6

2

3

5

4

7

DC 20

Water

0.66 Gal

2.5 l

1.32 Gal

5 l

1.98 Gal

7.5 l

Figure 40 Filling the solar installation using the “siphoning

principle”.

1

Domestic cold water connection;

2

and

4

Hose;

3

and

5

Cold water filling cock;

6

Container;

7

Canister for DC20 F.