EN-USA_SECUSOL_TI-MA-111013-1121R800

39

7 Maintenance and Care

Some components of the SECUSOL system are subject

to wear and have to be serviced regularly by expert per-

sonnel and, if required, replaced timely. See table 12 for a

list of wear components. For checking the sacrificial ano-

de the flange cover has to be opened. The flange cover

sealing and all flat sealing gaskets must be renewed after

each opening. See also tab. 8 on page 12.

Annual service checks are required, otherwise the warran-

ty is void:

●

Check for leaks at the storage cylinder and all connec-

tions. Look for signs of scaling or moist sections on the

insulation. Re-tighten connections if required.

●

Vent storage cylinder (follow steps as in chapter 4).

Hereunto remove storage lid and lid insulation.

●

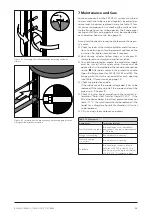

To check the protective anode, the cold water supply

must be shut off at the safety valve. A cock must be

opened that is situated below the hot water connection

nozzle

➐

. Afterwards remove the protective anode:

Open the flange cover for SECUSOL 250 and 350. The

flange gasket has to be renewed after each opening

(see Table 10 accessories, on page 12).

●

Check the protective anode.

If the substance of the anode is degraded, it has to be

replaced. Otherwise re-install the anode and vent the

pipe circuit. (Chapter 4).

●

Check the solar liquid according to the technical in-

formation “Solar Heat Transfer Liquid DC20 F” If the

PH Value drops below 6.6 or frost protection does not

reach -17 °C, the solar liquid should be replaced. If the

liquid has a stingy smell or black coloration, it also has

to be replaced.

●

Fill in and sign the maintenance records.

Table 12

Wear parts

Component

Inspection interval

Sacrificial anode on tank

Bi-annual inspection – durability is

dependent on domestic water quality,

2 - 10 years

Flange cover sealing

Renew after each opening

Flat seals on pipe

connectors

Renew after each opening

Solar fluid

Bi-annual inspection according to

data sheet DC20 F: pH value > 6.6

and frost protection up to a minimum

of 1.4 °F /-17 °C, otherwise replace

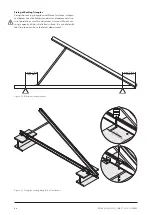

Figure 41 Attaching the jacket insulation by locking the hook

closure.

Figure 42 Insulation of the pipe connections overlapping with the

storage cylinder jacket insulation .