3

ASP 30

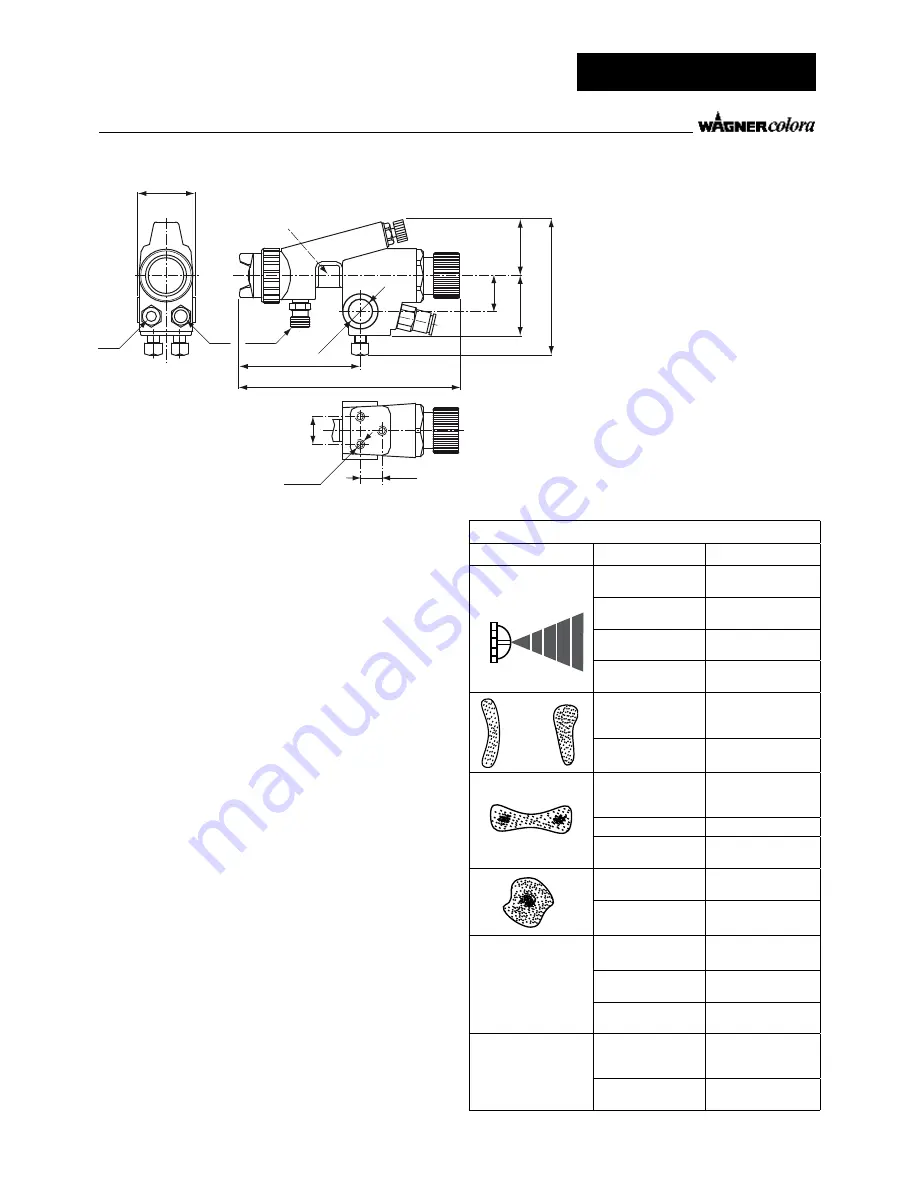

Ø6

G 1/4”

Ø10

38

Ø16

18

85,5

40,5

35,5

23,5

16,5

~ 148

3 x M8

~ 87,5

C

A

B

CA

E

D

F

C_ASP30_00002

Operating manual

editiOn 03 /2013

oPerATIoN

Install and operate the spray gun according to above figure.

Verify the cleanness of fluid and air hoses before connection.

Check that all connections are tight.

Keep the spray gun clean and lubricate moving parts at

regular intervals.

Lubricants for surface-treatment equipment must

not

contain silicon

.

In the event of leakage around the paint needle, tighten the

packing screw (see F in the above figure) . After tightening,

check that the spring is still able to push forward the fluid

needle.

For short standstill periods, for instance over a night, it will

suffice to clean the paint nozzles and the air cap on the outside;

for longer standstill periods the gun must be flushed through

immediately with appropriate solvent.

If a two-component paint is used, however, the

flushing

operation must be done no later than the pot-life time

(refer

to data sheet from the paint manufacturer).

When cleaning the air cap and the paint nozzle, use a soft

brush or rag dipped in solvent. Do not place the whole gun in

solvent to avoid damaging.

Never use iron or steel wire to clean air holes and ducts in the

nozzles.

Switch the on/off pneumatic control valve in advance to

compensate, if needed, the response time of the gun.

Recommended size for control valve: 3-way, G 1/4“.

CoNNeCTIoNS ANd CoNTroLS

A

Atomizing air hose connection (AA).

B

Paint hose connection.

C

Control air hose connection (CA).

d

Fan width adjustment.

Clockwise turning result in a round jet and

counter-clockwise turning in a wider fan.

e

Paint flow adjustment.

Clockwise turning result in a smaller

paint flow and counter-clockwise turning

increases the flow. The fluid flow is

regulated in the first instance by the choice

of paint nozzle and paint pressure.

f

Paint needle packing adjusting screw.

TrouBLe SHooTING

CAuSe

SoLuTIoN

Fluttering paint

Insufficient paint in the

supply bin

Refill the material bin

Blocked gun fluid

passage

Clean to remove the

blockage

Worn or loose fluid

nozzle

Replace or tighten

Worn or loose needle

seal packing

Replace or tighten

or

Paint build-up on

nozzle or un air cap

Clean fluid nozzle or

air cap (do NOT use

metallic object)

Dirty or damaged fluid

nozzle

Clean or replace fluid

nozzle

Insufficient paint

Increase

paint flow or reduce

atomizing air pressure

Too low paint viscosity

Increase viscosity

Too high atomizing air

pressure

Reduce atomizing air

pressure

Too high paint viscosity

Reduce viscosity

Too low atomizing air

pressure

Increase atomizing air

pressure

Dripping from fluid

nozzle

Partial seizing of the

needle

Lubricate needle

Too tight fluid needle

packing screw

Adjust

Worn fluid nozzle or

needle

Replace parts

Loss of paint from the

seal packing screw

(See F)

Loose fluid needle

packing screw

Tighten and check

fluid needle for free

movement

Dry or worn needle seal

packing

Replace or lubricate

All manuals and user guides at all-guides.com