© Wagner Spray Tech. All rights reserved.

5

English

Cleaning the Spray Gun

It is very important to clean your HVLP spray gun thoroughly after

each use.

1. Empty the spray material from the cup.

2. Pour a small amount of the appropriate solvent in the cup and

attach the cup to the spray gun.

3. Shake and spray the gun in a well ventilated area.

NOTE: Do not restrict the nozzle when cleaning. Back

flushing of the system is not necessary.

4. Repeat the steps above until the solvent appears clear.

5. Wipe the interior/exterior of the cup and the spray gun with

the appropriate solvent until it is clean.

6. Remove the needle, fluid nozzle, and air cap and clean

them thoroughly. Make sure that the air holes and material

passages are completely clean. Never use metal tools or picks

to clean the air cap or nozzle.

IMPORTaNT: any attempt to remove the fluid inlet fitting will

result in damage to the gun body and void the warranty.

NOTE: Remove the needle packing only when replacing

with a new needle packing. Do not remove the

needle packing for cleaning.

7. Disassemble, clean, and dry the check valve and air tubes after

each use.

IMPORTaNT: DO NOT clean the air tubes with hot solvents such as

lacquer thinner. hot solvents will damage the air tubes.

NOTE: Lubricate all of the threaded parts on the spray

gun with petroleum jelly when you put them back

together. This will help keep them working properly.

IMPORTaNT: Do not use any lubricants containing silicone.

Silicone can cause problems when used with some paints.

Maintenance

Perform the following maintenance procedures to keep your HVLP

spray gun working properly.

adjusting the Packing Nut

If material leaks from around or through the packing nut, readjust the

packing nut.

1. Disconnect the air hose from the air inlet and remove the cup

assembly.

2. Pull the trigger all the way back and hold.

3. Tighten the packing nut using a 3/8 inch wrench until the

needle remains retracted inside the nozzle when you release

the trigger.

Packing Nut

4. Loosen the packing nut slowly

until the needle moves freely

back into position in the nozzle.

Once you have adjusted the nut,

reconnect the air hose and the cup

assembly. Squeeze the trigger to see if

the leaking has stopped. If it has not,

make sure the packing nut is as tight as

possible, while allowing the needle to

move freely. If adjusting the packing

nut does not stop the leak, replace the

packing.

Replacing the Needle Packing and air valve Seals

NOTE: Remove the needle packing only when replacing

with a new needle packing. Do not remove the

needle packing for cleaning.

The needle packing and the air valve seals can be

replaced separately. If you are replacing only one of

them, use the appropriate steps from the following

procedures.

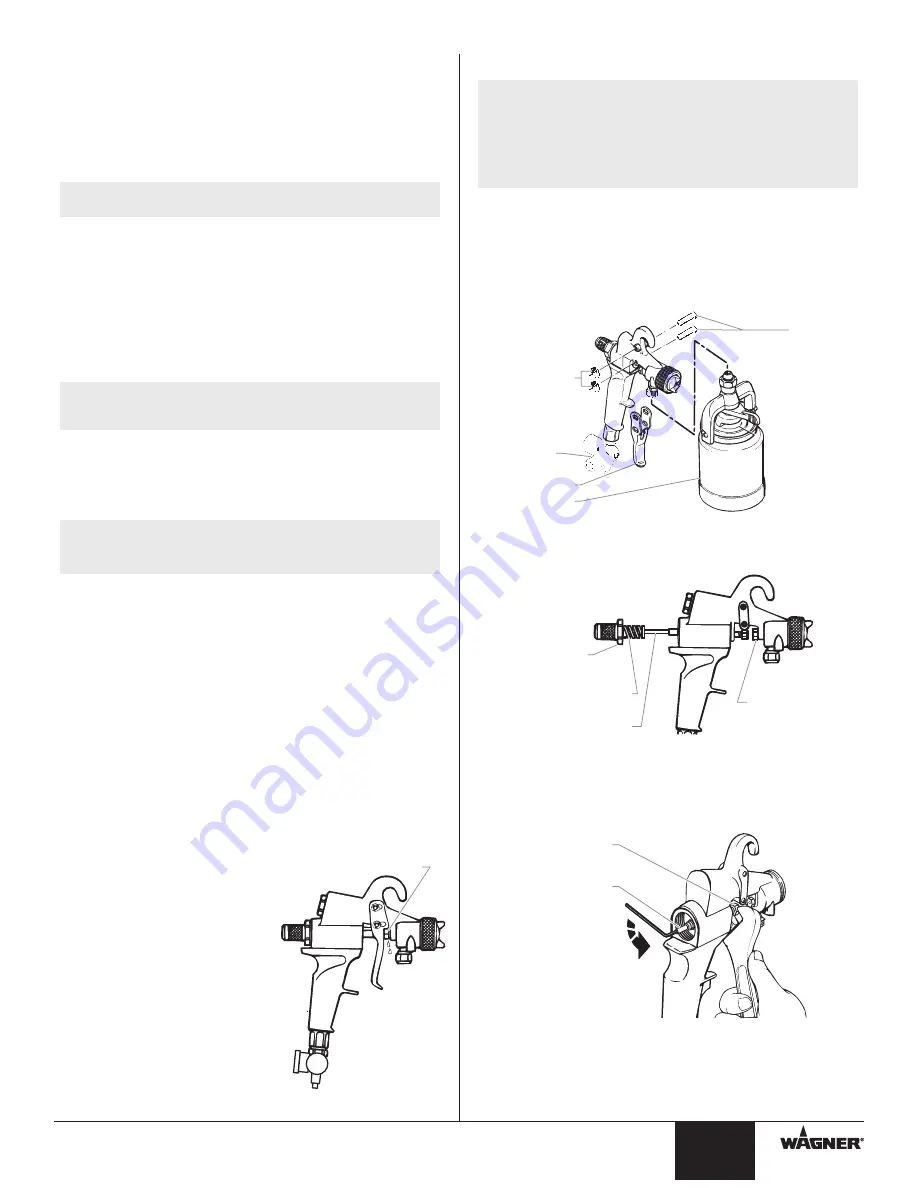

Removing the Needle and housing

1. Disconnect the air hose from the air inlet.

2. Remove the material hose or cup assembly.

3. Remove the snap rings from the trigger retaining pins and

slide the pins out of the gun.

4. Remove the trigger.

Trigger

Retaining

Pins

Snap Rings

Regulator

Trigger

Cup Assembly

5. Loosen the packing nut using a 3/8 inch wrench.

6. Loosen and remove the material flow adjustment housing,

needle, seal, and spring using a wrench.

Material

Adjustment

Housing

Seal and

Spring

Needle

Packing Nut

7. Insert an 1/8 inch hex wrench into the back of the needle

guide shaft.

8. Hold the retaining nut with a wrench and turn the 1/8 inch

hex wrench counterclockwise to remove the retaining nut.

9. Pull the needle guide shaft out of the gun body.

Retaining Nut

Needle

Guide Shaft