© 1995 Wagner Spray Tech

8

All rights reserved.

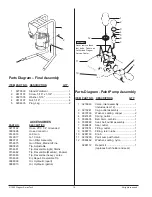

1. Lay the unit back on its handle so that the inlet valve

is facing up. Fill the inlet valve with water or with a

light household oil.

2. Make certain that the PRIME/SPRAY knob is set to

PRIME ( ) and that the pressure control knob is

turned counterclockwise to the lowest pressure

setting.

3. Turn the motor switch to ON.

4. Increase the pressure by turning the pressure

control knob clockwise 1/2 turn.

5. Force the inlet valve to open and close by pushing

on it with a screwdriver or the eraser end of a

pencil. It should move up and down about 1/16 of

an inch. Continue until water or oil is sucked into

the sprayer. This will wet the moving parts and

break loose any old paint residue.

6. Put the palm of your hand over the inlet. Turn the

pressure control knob clockwise to its maximum

setting. You should feel suction coming from the

inlet valve. If you do not, see the section on clean-

ing and servicing the outlet valve.

7. Turn the pressure control knob counterclockwise to

the minimum pressure setting.

8. Turn the motor switch to OFF.

9. Return the unit to an upright position.

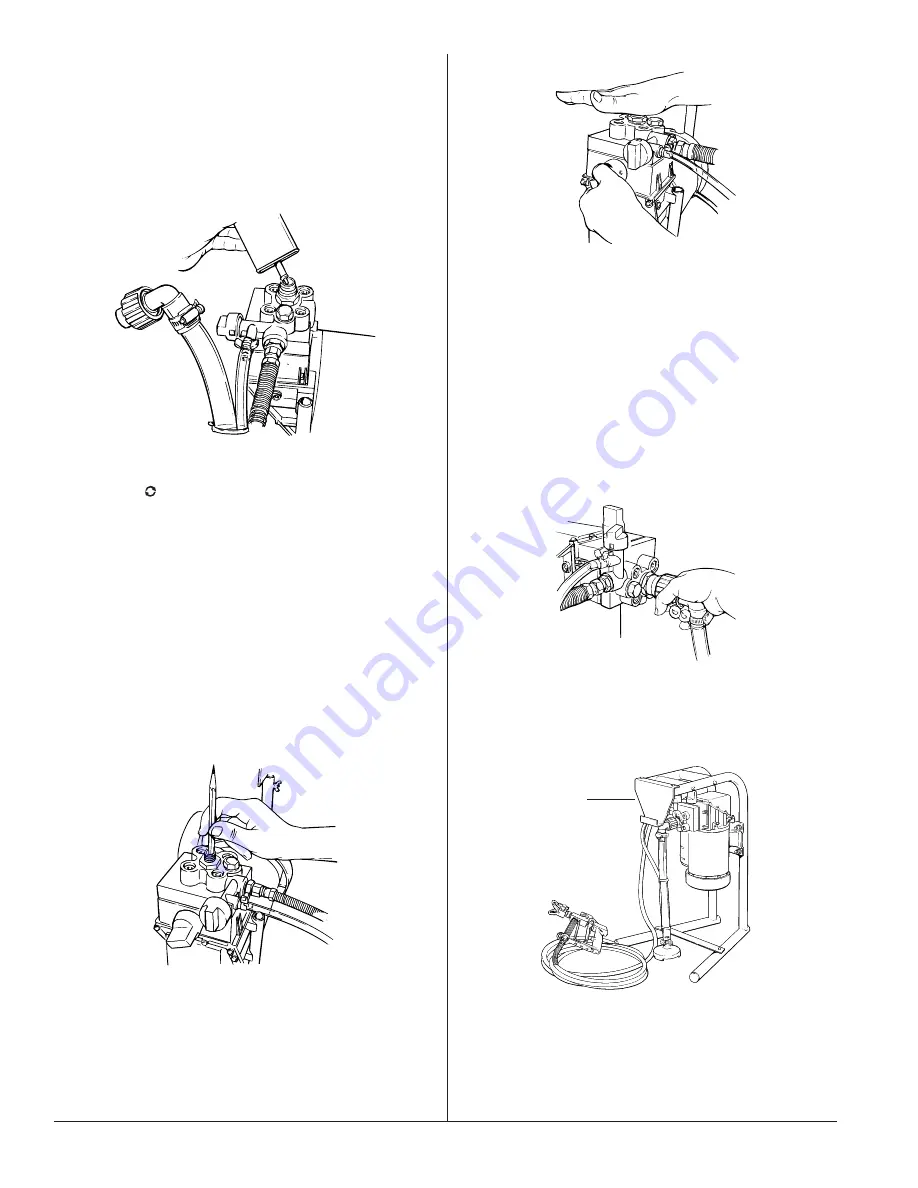

1. Attach the suction tube to the inlet valve and tighten

firmly by hand. Be sure that the threads are straight

so that the fitting turns freely.

2. Place the suction tube and the return tube into the

paint.

3. Hang the paint bucket onto the pail bracket.

1. Turn the pressure control knob counterclockwise to

its lowest pressure setting.

Pail Bracket