14

Pole Gun

GB

Introduction

This airless spray gun is to be used for the high pressure atomization of liquid coating materials.

The spray gun corresponds with Ex II 2G X and is, in accordance with Directive 94/9/EEC

(Atex 100a), suitable for use in explosion-hazardous areas—as of type Zone 1. Under certain

circumstances, the unit itself may cause the Zone 1 condition to be in effect.

X marking: Any static-electricity discharge from the spray gun is to be diverted to the grounded high-

pressure pump via the conductive high-pressure hose as stipulated.

To avoid the generation of machine sparks, prevent impact stresses and any work on the unit with

tools in the explosion-hazardous area.

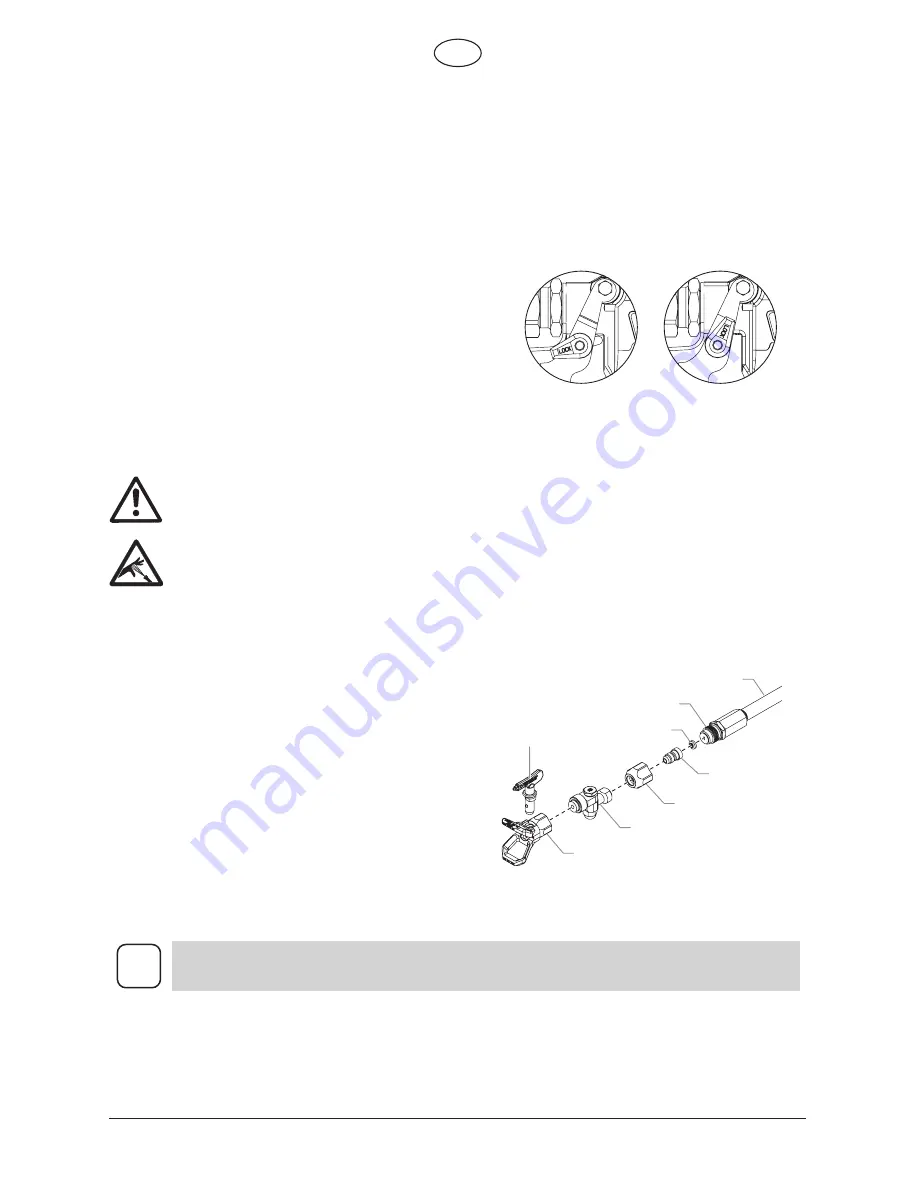

Using the Gun Trigger Lock

Trigger locked

(gun will not spray)

Trigger unlocked

(gun will spray)

Always engage the gun’s trigger lock when the gun is

not in use.

1. To lock the trigger, rotate the trigger lock

forward until it stops.

2. To unlock the trigger, rotate the trigger lock

backward until it is vertical.

Setup

Never attempt to assemble, change, or clean the gun, tip, or tip guard without first

relieving pressure from the spray system. Follow the “Pressure Relief Procedure” in

the sprayer’s Owner’s Manual.

Always use a tip safety guard for added protection against injection. Beware that the

guard alone will not prevent injection. Never cut off tip guard! Always engage gun

trigger lock when the gun is not in use. Before servicing equipment, consult Owner’s

Manuals and follow all warnings.

1. Set up the sprayer. Refer to the instructions in the sprayer’s Owner’s Manual.

2. Attach a grounded, airless spray hose to the material inlet on the gun. Using two wrenches

(one on the gun and one on the hose), tighten securely.

Extension Pole

Diffuser

Seal Washer

Pole Mount

Retaining Nut

Tip Swivel

Tip Guard

Tip

3. With the tip, tip swivel, and tip guard off the

gun, start the sprayer. Flush and prepare

the spray system according to the sprayer’s

Owner’s Manual. Inspect the spray system to

make sure that all fittings are secure and that

there are no leaks.

4. Perform the “Pressure Relief Procedure”

described in the sprayer’s Owner’s Manual.

5. Place the seal washer and pole mount over

the diffuser, and secure in position using

the retaining nut. Tighten securely using a

wrench.

6. Thread the tip swivel onto the pole mount.

Tighten securely using a wrench.

7. Insert the tip into the slot on the tip guard. Thread the tip guard onto the tip swivel. Tighten

securely using a wrench.

i

The arrow on the tip handle should be pointing in the forward direction for

spraying.