8

GB

9. Switch the unit off.

10. Clean the outer surfaces of the paint container and paint

spray gun with a cloth soaked in solvent or water.

Note:

Do not leave the FineCoat spray gun immersed

in solvent for extended periods! (The seals and air pipe

on non-return valve may swell, preventing them from

functioning properly.)

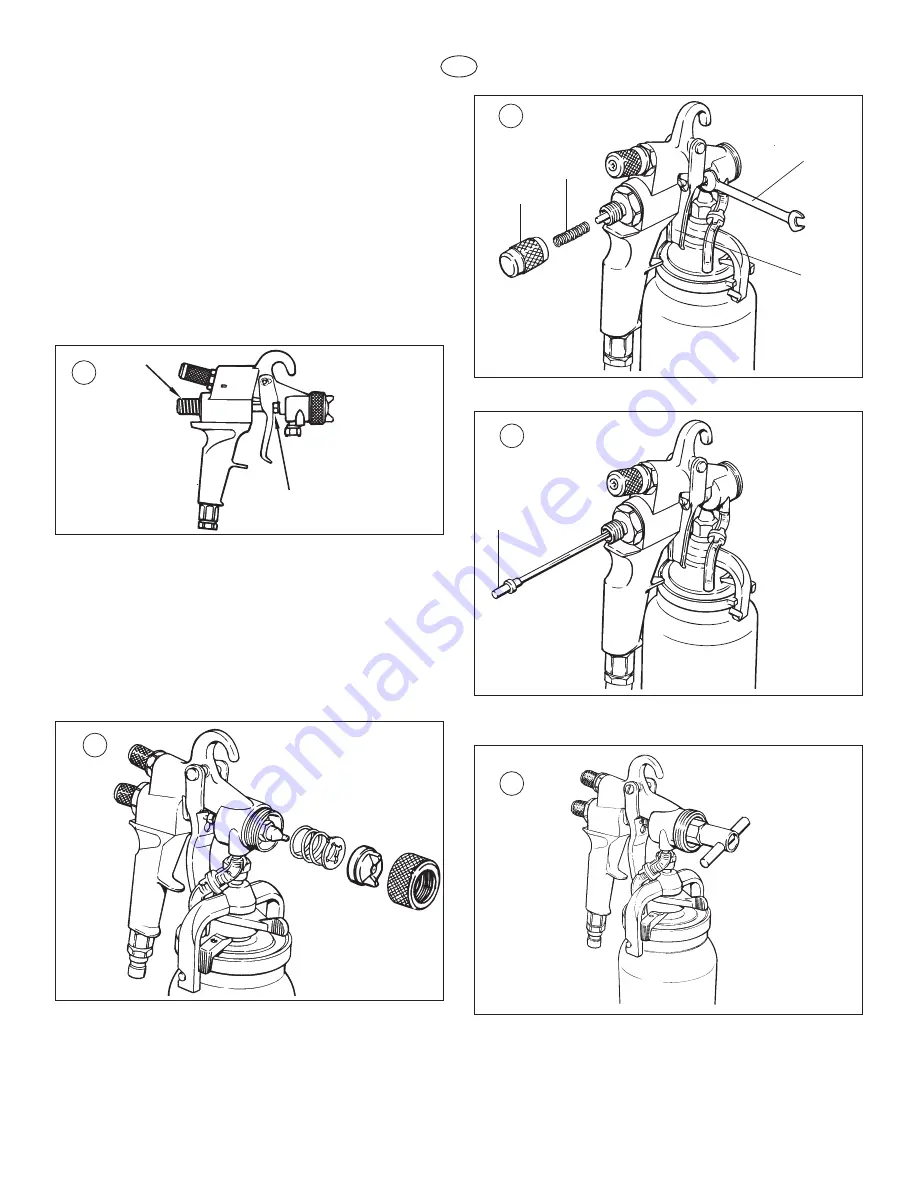

11. Unscrew adjusting ring, remove air cap and spring plate

(fig. 13). Unscrew nozzle. Clean air cap, tip and needle

with brush and solvent or water.

Note:

Never use sharp metal objects to clean the nozzles

or air channels of the FineCoat spray gun.

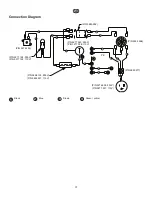

12. Apply a fine coat of silicone-free oil to the marked areas

(fig 12).

12

13. If the paint spray gun is not used for any length of time, it

should be cleaned and protected by applying a fine coat of

silicone-free oil..

Changing the nozzle

Note:

Make sure that the air cap, the tip and the needle have

identical markings.

1. Remove the adjusting ring, the air cap and the spring

plate (fig. 13).

13

2. Fig. 14 – Loosen the needle seal with the open-end

wrench (fig. 14,1). Remove the material adjusting knob

(fig. 14,2) and the pressure spring (fig. 14,3). Open trigger

of the spray gun to facilitate needle removal (fig. 14,4).

2

3

4

1

14

3. Remove the needle (fig. 15,5).

5

15

4. Remove the tip with the enclosed special socket wrench

(fig. 16).

16

Reassemble with the new nozzle set in reverse order.

Attention:

The needle seal screw connection must be

readjusted after reassembly.