20

servicing / repairs at the unit

ps 3.21

10

ServIcINg

10.1

geNerAl ServIcINg

Servicing of the unit should be carried out once annually by the

WAGNER service.

1. Check high-pressure hoses, device connecting line and

plug for damage.

2. Check the inlet valve, outlet valve and filter for wear.

10.2

hIgh-preSSure hoSe

Inspect the high-pressure hose visually for any notches or

bulges, in particular at the transition in the fittings. It must be

possible to turn the union nuts freely.

i

The risk of damage rises with the age of the high-

pressure hose. Wagner recommends replacing

high-pressure hoses after 6 years.

11

repAIrS AT The uNIT

Switch the unit OFF.

Before all repair work: Unplug the power plug

from the outlet.

i

Make sure to check for grounding continuity

after service is performed on any electrical

components.

Use an ohmmeter to determine that there is

continuity between accessible dead-metal parts

of the product and the grounding blade of the

attachment plug.

11.1

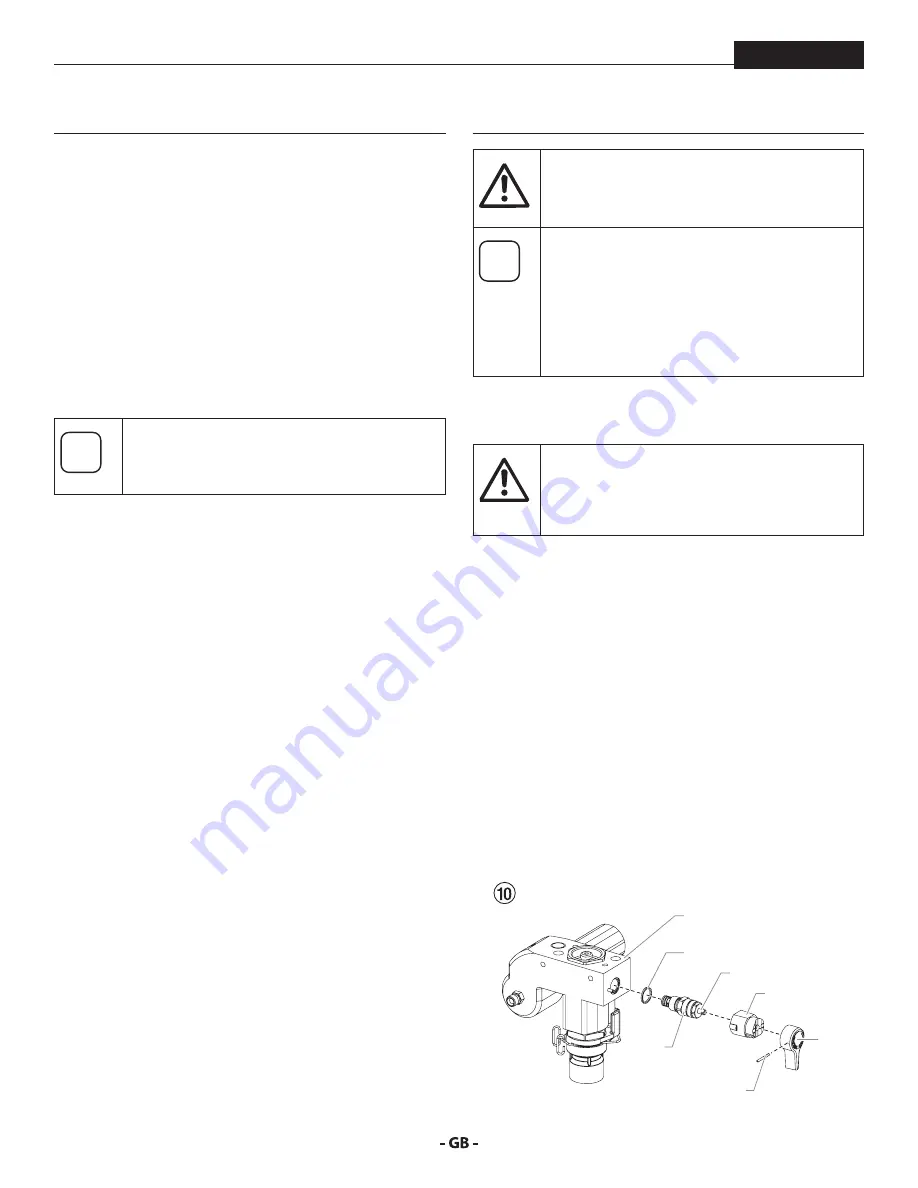

relIef vAlve

Attention

The valve housing (4) should not be repaired. If

worn, it should always be replaced with a new

one.

1. Use a drift punch of 2 mm to remove the grooved pin (Fig.

10, Item 1) from the relief valve handle (2).

2. Remove the relief valve handle (2) and cam base (3).

3. Using a wrench, remove the valve housing (4) from the

pump manifold (6).

4. Ensure that the seal (5) is seated correctly, then screw the

new valve housing (4) completely into the pump manifold

(6). Tighten securely with a wrench.

5. Align the cam base (3) with the hole in the pump manifold

(6). Lubricate the cam base with grease and slide on the

cam base.

6. Bring the hole in the valve shaft (7) and in the relief valve

handle (2) into alignment.

7. Insert the grooved pin (1) to secure the relief valve handle

in position.

3

7

4

1

2

6

5