Finish 230 AC Compact

11

GB

Spraying

Spraying Technique

5.3

Pressure Relief Procedure

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for

cleanup.

1. Turn the pressure control knob counterclockwise to its lowest

setting.

2. Turn the PRIME/SPRAY valve to the PRIME position.

3. Trigger the gun to remove any pressure that still may be in the

hose.

4. Lock the gun by turning the gun lock nut clockwise (when

looking from the back of the gun) until it stops. This closes the

material valve in the gun.

Injection hazard. Do not spray without the tip guard

in place. NEVER trigger the gun unless the tip is

completely turned to either the spray or the unclog

position. ALWAyS engage the gun trigger lock

before removing, replacing or cleaning tip.

6.

Spraying Technique

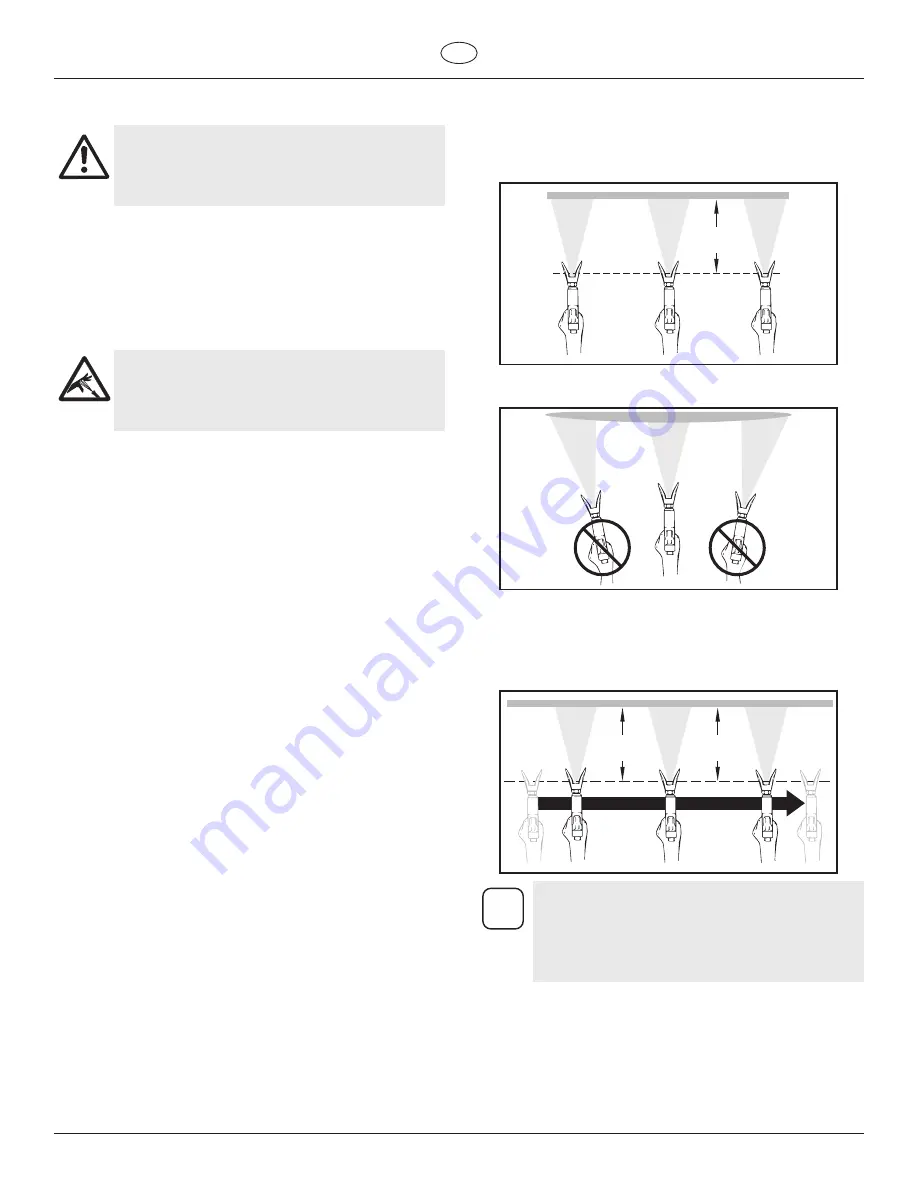

The key to a good paint job is an even coating over the entire surface.

Keep your arm moving at a constant speed and keep the spray gun at

a constant distance from the surface. The best spraying distance is 25

to 30 cm between the spray tip and the surface.

25 - 30 cm

Keep the spray gun at right angles to the surface. This means moving

your entire arm back and forth rather than just flexing your wrist.

Keep the spray gun perpendicular to the surface, otherwise one end

of the pattern will be thicker than the other.

Trigger gun after starting the stroke. Release the trigger before

ending the stroke. The spray gun should be moving when the trigger

is pulled and released. Overlap each stroke by about 30%. This will

ensure an even coating.

25 - 30 cm

25 - 30 cm

i

When finished spraying, perform Pressure Relief

Procedure.

If you expect to be away from your spray project

for more than 1 hour, follow the Overnight Storage

procedure described in the Cleanup section of this

manual.