8

Finish 230 AC Compact

GB

Operation

4.

Operation

Use the following procedures to operate the spray system.

4.1

Preparing to Prime

1. Fill the inlet valve with water or with a light household oil.

2. Make sure that the PRIME/SPRAY valve is set to PRIME and that

the pressure control knob is turned counterclockwise to its

lowest pressure setting.

3. Turn on the pump by moving the pump ON/OFF switch to the

ON position.

4. Increase the pressure by turning the pressure control knob

clockwise 1/2 turn.

5. Force the inlet valve to open and close by pushing on it with a

screwdriver or the eraser end of a pencil. It should move up and

down about 1.5 mm. Continue until water or oil is sucked into

the pump. This will wet the moving parts and break loose any

old paint residue.

6. Put the palm of your hand over the inlet. Turn the pressure

control knob clockwise to its maximum setting. You should

feel suction coming from the inlet valve. If you do not, refer to

the “Removing and Cleaning the Outlet Valve” procedure in the

Maintenance section.

7. Turn the pressure control knob counterclockwise to the

minimum pressure setting.

8. Turn the pump ON/OFF switch to OFF.

4.2

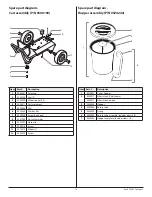

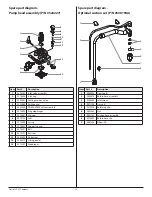

Priming with Hopper Assembly

1. Attach the hopper assembly to the pump.

a. Screw the return tube fitting into the return tube port on

the side of the pump.

i

Do not over-tighten. Hand tighten only. Some

threads will be visible even when fully tightened.

b. Thread the return hose onto the return hose fitting on the

pump.

c. Turn the paint hopper clockwise to thread it onto the inlet

valve. Continue to turn the paint hopper until it is secure

on the inlet valve.

i

Make sure the threads are straight and the hopper

turns freely on the inlet valve. Do not cross-thread.

d. Place the filter screen into the bottom of the paint hopper

and snap it in position.

e. Make sure that the motor ON/OFF switch is turned to OFF.

f. Place the straight end of the return tube into the return

tube fitting.

g. Thread the nut on the return tube fitting and tighten until

the return tube is secure.

h. Place the hook end of the return tube into the hole in the

paint hopper cover.

2. Turn the pressure control knob counterclockwise to its lowest

pressure setting.

3. Remove the paint hopper cover and fill the paint hopper with

material or place the suction set into a bucket of material.

4. Turn the PRIME/SPRAY valve to PRIME.

5. Move the motor ON/OFF switch to ON.

6. Turn the pressure control knob clockwise to between half and

full pressure. Let the unit prime 1 to 2 minutes after material

begins to flow through the return tube.

1

2

5

4.1

4.1

4.2

1a

1f

1b

1g

1c

1h

Attention

Always reduce the pressure to zero by triggering

the spray gun before changing the position of the

PRIME/SPRAy valve. Failure to do so may cause

damage to the paint pump diaphragm.

If the pressure control knob is reduced to zero and

the PRIME/SPRAy valve is still on SPRAy while the

pump is operating, there will be high pressure in the

hose and spray gun until the PRIME/SPRAy valve is

turned to PRIME or until the spray gun is triggered to

relieve the pressure.