24

VERSION 03/2018

ORDER NUMBER DOC 2369735

5.2

MODE OF OPERATION

The AquaCoat spray system is designed for processing non-ignitable liquids (water lacquers)

in accordance with the air spraying method.

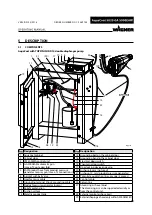

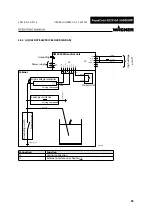

The VM 5020WA control unit (3) regulates the high voltage. The spray product is drawn in

with a product pressure generator (11) via a suction system (13), electrostatically charged

in the sealed off inner chamber of the AquaCoat cabinet (1), and sprayed in the nozzle of

the spray gun with the help of atomizing air.

The product pressure generator and spray gun are connected by the shielded product hose.

5.3

PROTECTIVE AND MONITORING EQUIPMENT

WARNING

Protective and monitoring equipment!

Risk of injury and damage to the device.

Protective and monitoring equipment must not be removed, modified or rendered

unusable.

Regularly check for perfect functioning.

If defects are detected on protective and monitoring equipment, the system must not

be operated until these defects are remedied.

The following elements are provided for system safety:

Safety element

Function

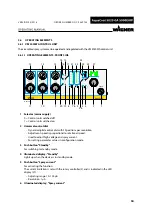

Grounding switch (30)

Grounding the potential equalization lines and pump support.

Electrical door switch (17)

The grounding switch is closed with an open cabinet door

(potential equalization lines are grounded).

Pneumatic door switch (18)

Leakage resistance (32)

Reduces the high voltage in a controlled manner.

Door lock

Cabinet door can not be opened when the control unit is

switched on.

Grounding band (16) in the

cabinet door.

The grounding band is grounded over the pneumatic door

switch with a closed cabinet door.

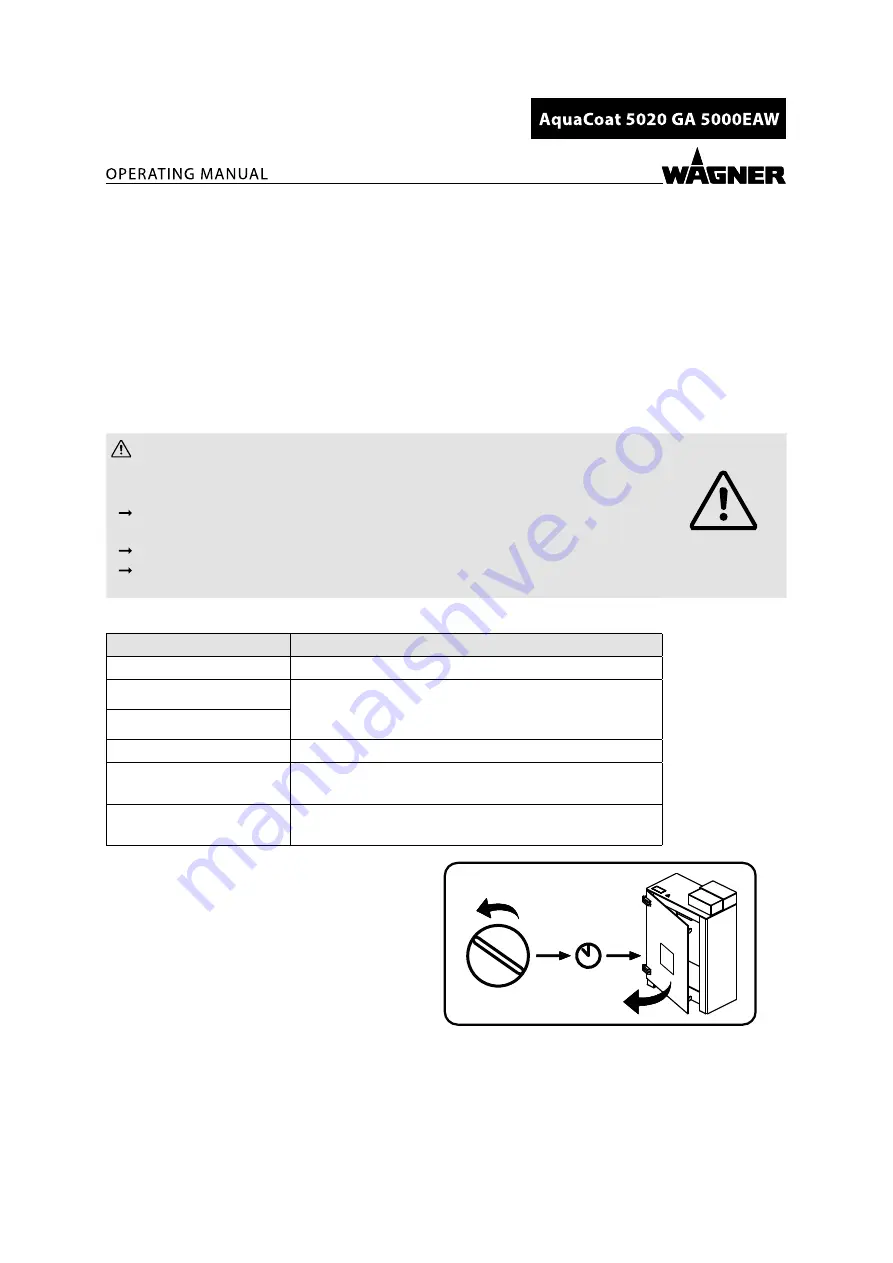

Door lock

Only open or close the cabinet door (2) when the

control unit (3) is switched off.

One second after the control unit (3) has been

switched off, the system is grounded and the door

lock opened.

B_05871

0

1

1 s

Power