125

B_03699

B_04764

B_05892

B_05893

B_05894

B_05895

B_05986

B_05987

OPERATING MANUAL

EDITION 02/2016

ORDER NUMBER DOC 2366600

Order No.

Designation

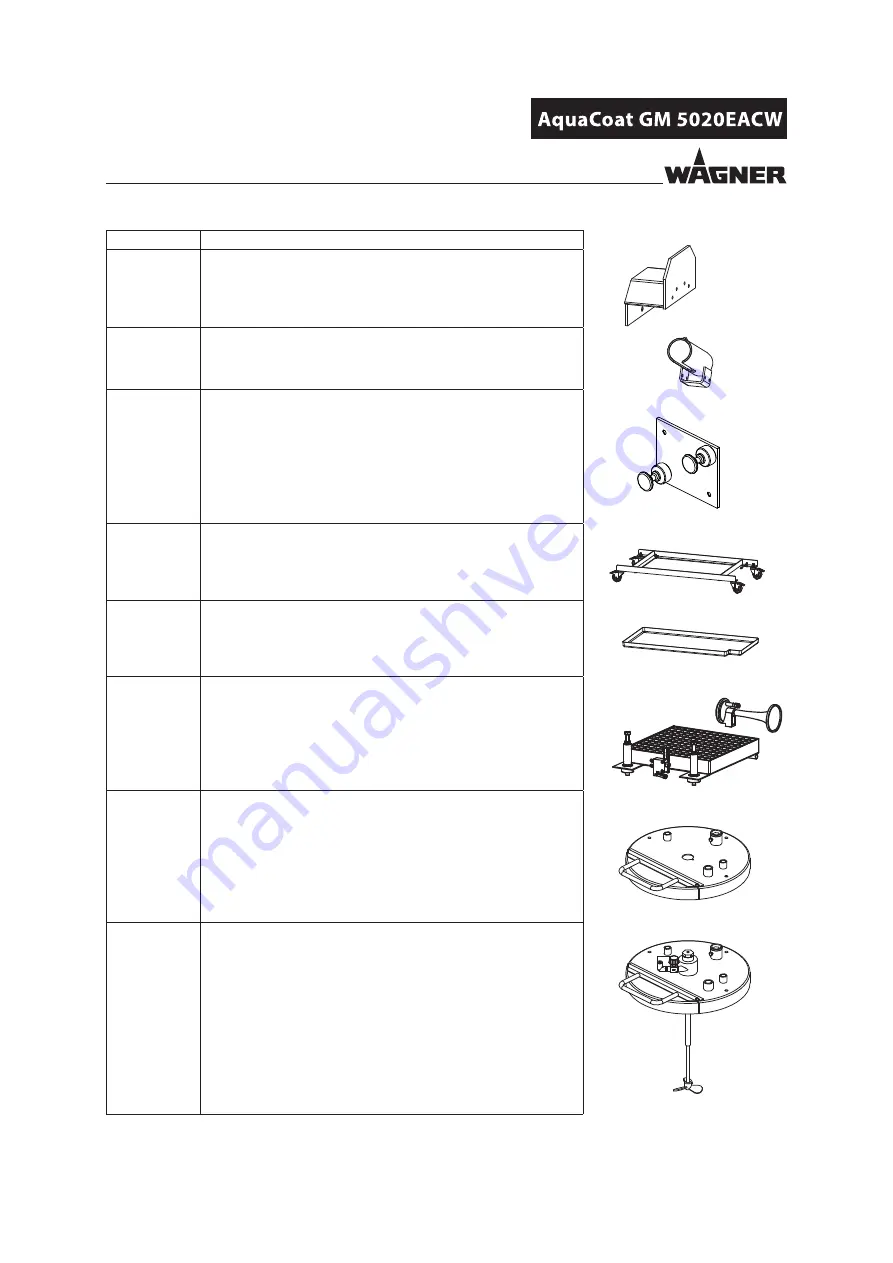

353050

Hose holder

2359097

Gun holder.

For assembly on hose holder 353050.

2326485

Wall mount, GM 5000E (left/right)

2359029

Underframe, 5020 with rolls

2364394

Underframe, 5010 with rolls

2364791

Tub insert, 5020

2364790

Tub insert, 5010

353053

Level monitor, incl. alarm horn

353054

Drum cover, D350 without agitator

353055

Drum cover, D350 with agitator

Summary of Contents for AquaCoat 5010

Page 2: ......

Page 72: ...72 OPERATING MANUAL EDITION 02 2016 ORDER NUMBER DOC 2366600...

Page 159: ......