50

OPERATING MANUAL

EDITION 02/2016

ORDER NUMBER DOC 2366600

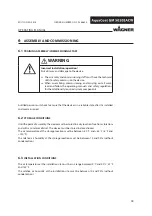

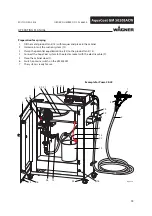

It is important for systems safety and to achieve an optimum coating that all system

components such as work pieces, conveyors, paint supply, control unit and booth or

spraying stand are perfectly grounded.

6.6

GROUNDING

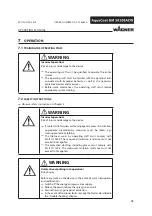

Heavy paint mist if grounding is insuffi

cient!

Danger of poisoning.

Insuffi

cient paint application quality.

Ground all device components.

Ground the work pieces to be coated.

WARNING

A poorly grounded work piece causes:

- very poor wrap-around,

- uneven coating,

- back spraying to the spray gun, i.e., contamination.

Prerequisites for perfect grounding and coating are:

- Clean work piece suspension.

- Grounding of spray booth, conveyor system and suspension on the building side in

accordance with the operating manuals or the manufacturer's information.

- Grounding of all conductive parts within the working area.

- The grounding resistance of the work piece may not exceed 1 MΩ (megaohm) (ground

leakage resistance measured at 500 V or 1000 V).

- Connect the AquaCoat cabinet to the signal ground.

- Connect all ground cables using a short and direct route.

- Safety shoes and gloves, if used, must be static dissipative.

Summary of Contents for AquaCoat 5010

Page 2: ......

Page 72: ...72 OPERATING MANUAL EDITION 02 2016 ORDER NUMBER DOC 2366600...

Page 159: ......