57

OPERATING MANUAL

EDITION 02/2016

ORDER NUMBER DOC 2366600

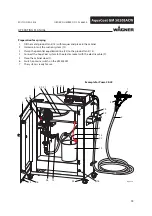

Check the unit for leaks

1.

Clamp the potential equalization line (22) to pump's product connection.

2.

Fill the upper tank (14) with a suitable medium (e.g., fl ushing agent or water).

3.

Guide return hose (26) into upper tank.

4.

To perform a leak test on the entire installation, the pressure is slowly increased step

by step until the maximum pressure as indicated on the type plate for the system

and product pressure generator fi tted is reached.

AquaCoat with Cobra 40-10: "Pump pressure" regulator up to 0.6 MPa; 6 bar; 87 psi

5.

Maintain the pressure for 5 minutes and check all connecting parts for leaks.

6.

Reduce the pressure, when the seal of the system has been ascertained.

7.

Flush system through well Chapter 8.1.3.

8.

Relieve system pressure Chapter 7.3.4.

9.

Secure the spray gun (4) using the trigger lock.

10. Remove fl ushing agent.

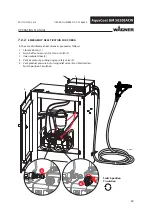

Preparation for spraying

1.

Fill upper tank (14) with lacquer.

2.

Clamp the potential equalization line (22) to pump's product connection.

3.

Connect the AquaCoat system to the electric socket with the electric cable (9).

4.

Close the cabinet door (2).

5.

Switch on mains switch on the VM 5020W.

6.

The system is ready for use.

A skilled person must check to ensure that the device is in a reliable state after it is installed

and commissioned.

This includes:

- Carry out a safety checks in accordance with Chapter 8.2.3.

- Function test in accordance with Chapter 11.

6.9.4

VERIFYING A SAFE OPERATIONAL CONDITION

Summary of Contents for AquaCoat 5010

Page 2: ......

Page 72: ...72 OPERATING MANUAL EDITION 02 2016 ORDER NUMBER DOC 2366600...

Page 159: ......