60

AquaCoat GM 5000EACW

OPERATING MANUAL

EDITION 04/2012

PART NO. DOC2321362

5.5

DEVICE CONFIGURATION

5.5.1

OVERVIEW OF PARAMETERS

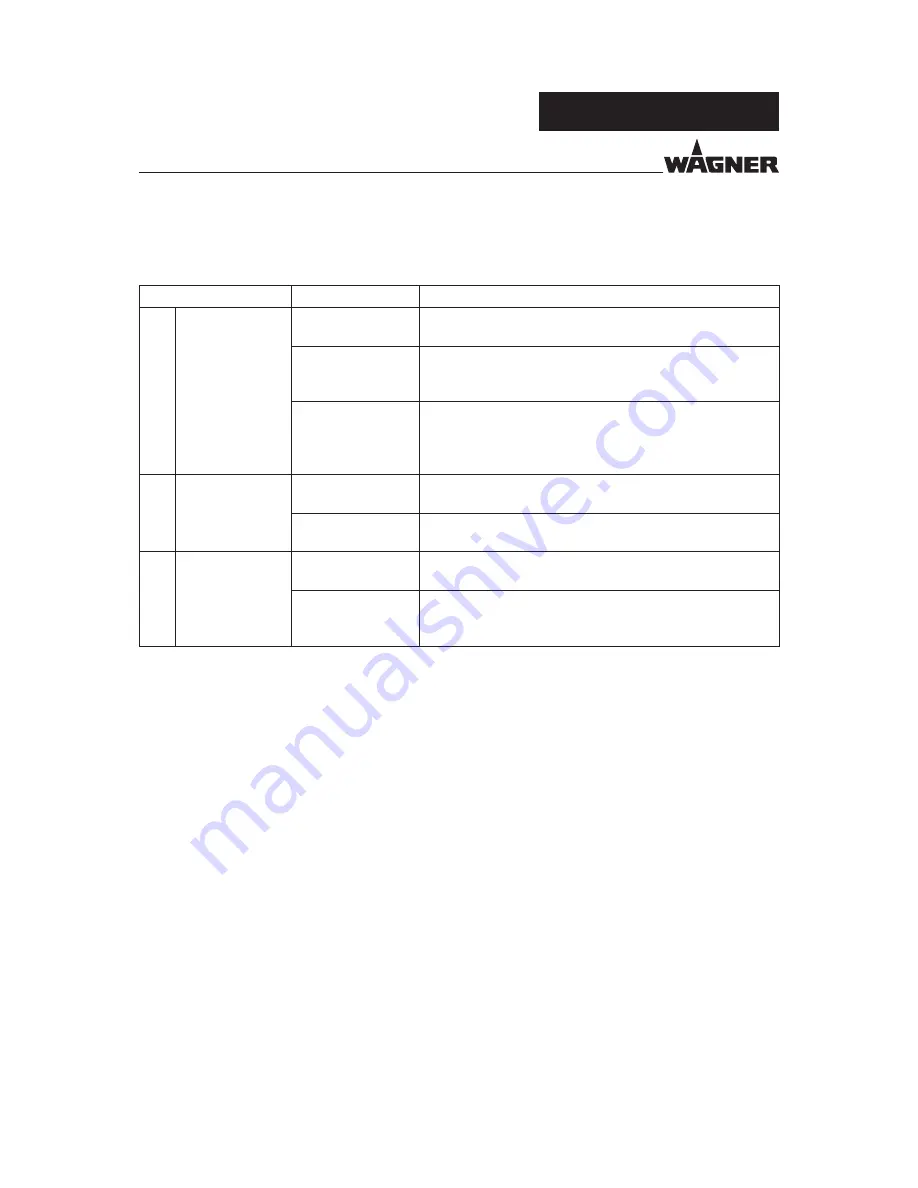

Parameters

Value

Description

C13

User lock

off

(Factory setting)

User lock is switched off.

on

User lock is switched on: no target values (kV and µA) can

be adjusted; you can only select the recipe and the control

functions.

pro

User lock pro (program)

You can select recipes and control functions.

The target values (kV and µA) can be adjusted but cannot

be saved in the recipes.

C19

Reset recipes

no

(Factory setting)

No reaction

res

All programs are set to delivery status when “res” is saved

by the maintenance key.

C20

Reset

confi guration

no

(Factory setting))

No reaction

res

All confi guration parameters are set to delivery status

(factory setting) when “res” is saved by the maintenance

key.

Summary of Contents for AquaCoat AirCoat GM 5000EACW

Page 2: ......

Page 38: ...38 AquaCoat GM 5000EACW OPERATING MANUAL EDITION 04 2012 PART NO DOC2321362 ...

Page 92: ...92 AquaCoat GM 5000EACW OPERATING MANUAL EDITION 04 2012 PART NO DOC2321362 ...

Page 101: ...101 AquaCoat GM 5000EACW OPERATING MANUAL EDITION 04 2012 PART NO DOC2321362 ...

Page 111: ......