32

VERSION 01/2018

ORDER NUMBER DOC 2340851

Cobra 40-10 / 40-25

7.5

BASIC CLEANING

Flush regularly

Regular flushing, cleaning and maintenance ensures the pumps' high pumping and

suction capacity.

The cleaning and flushing agents used must be compatible with the working

material.

WARNING

Incompatibility of flushing / cleaning agent with the working medium!

Risk of explosion and danger of poisoning by toxic gases.

Examine the compatibility of the flushing and cleaning agents and working media

on the basis of the safety data sheets.

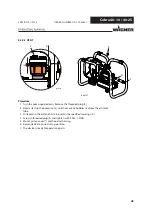

Procedure

6

1

9

2

7

4

5

B_04240

3

1. Visual check: personal safety equipment, grounding

and all devices ready to use.

2. Place empty tank (5) under return tube (4).

3. Place suction hose (7) in a tank with cleaning agent

(6).

4. Adjust the pressure regulator (1) to approx. 0.05 MPa;

0.5 bar; 7.25 psi.

Flushing via return tube

5. Open relief valve (3).

6. Slowly open the ball valve (2).

7. Adjust the air pressure on the pressure regulator (1)

so that the pump runs smoothly.

8. Rinse the system until the cleaning agent that flows

into the tank (5) is clean.

9. Close ball valve (2).

Flushing via spray gun

10. Reverse the relief valve (3).

11. Point the spray gun, without nozzle, into the tank (5) and open it.

12. Slowly open the ball valve (2).

13. Flush until clean cleaning agent flows from the spray gun.

14. Close ball valve (2).

15. When there is no pressure remaining in the system, close the spray gun.

16. Secure the spray gun.

17. Dispose of the contents of the tank (5) according to the local regulations.

Note:

B_01219

V

During the flushing procedure, briefly press both valve

depressors (V).

7.5.1 FILLING WITH WORKING MATERIAL

After basic flushing, the pump can be filled with working material. Proceed according to

Chapter

, but use working material instead of flushing agent.

Summary of Contents for Cobra 40-10

Page 1: ...B_04233 B_04234 Cobra 40 10 Cobra 40 25 High pressure Double Diaphragm Pumps Version 01 2018...

Page 2: ......

Page 49: ......

Page 69: ......

Page 83: ......