1

1

2

3

6

4

5

TAPER

2

7

8

EN

17

MAINTENANCE - CLEANING THE INLET VALVE

i

Cleaning or servicing the inlet valve may be required if the unit has priming problems.

Priming problems may be prevented by properly cleaning the sprayer and following the

long-term storage steps.

YOU WILL NEED

•

8 mm (5/16”) hex wrench

•

Needle nose pliers

•

Warm, soapy water if using latex material

•

Mineral spirits for oil based material

•

Household oil (such as 10W30 motor oil or vegetable oil for example)

1.

Perform the Pressure Relief Procedure, found in the main instruction

manual, to ensure the pump is shut off and depressurized. Remove

the tank lid.

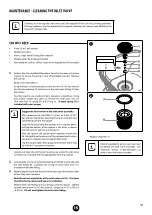

Remove the inlet filter (1).

Using the lid as a tray for the parts, insert an 8 mm (5/16”) hex wrench

into the hex opening (2) and unscrew the inlet valve fitting (2) from

the sprayer.

You may need to use a ball point pen, tweezers, screwdriver, O-ring

pick, and/or needle nose pliers to remove the inlet valve seat (3),

inlet valve ball (4), spring (5), and O-ring (6). A spare spring (5) is

included with your sprayer.

i

Suggestion for removal of the inlet valve assembly

After removing the inlet filter (1) insert an 8 mm (5/16”)

hex wrench into the hex opening (2) and unscrew the inlet

valve fitting (2) from the sprayer.

Snap the lid back onto the sprayer, turn it upside down,

and tap the bottom of the sprayer a few times to loosen

the inlet seat (3), ball (4), and spring (5).

With the sprayer still upside down carefully remove the

lid. Be careful not to lose any of the removed parts unless

you plan to replace them instead of clean them.

Flip the sprayer right-side up again and remove the O-ring

(6) with an O-ring pick or tweezers.

Inspect and clean the inlet valve housing area where the inlet valve

assembly was removed with the appropriate cleaning solution.

2.

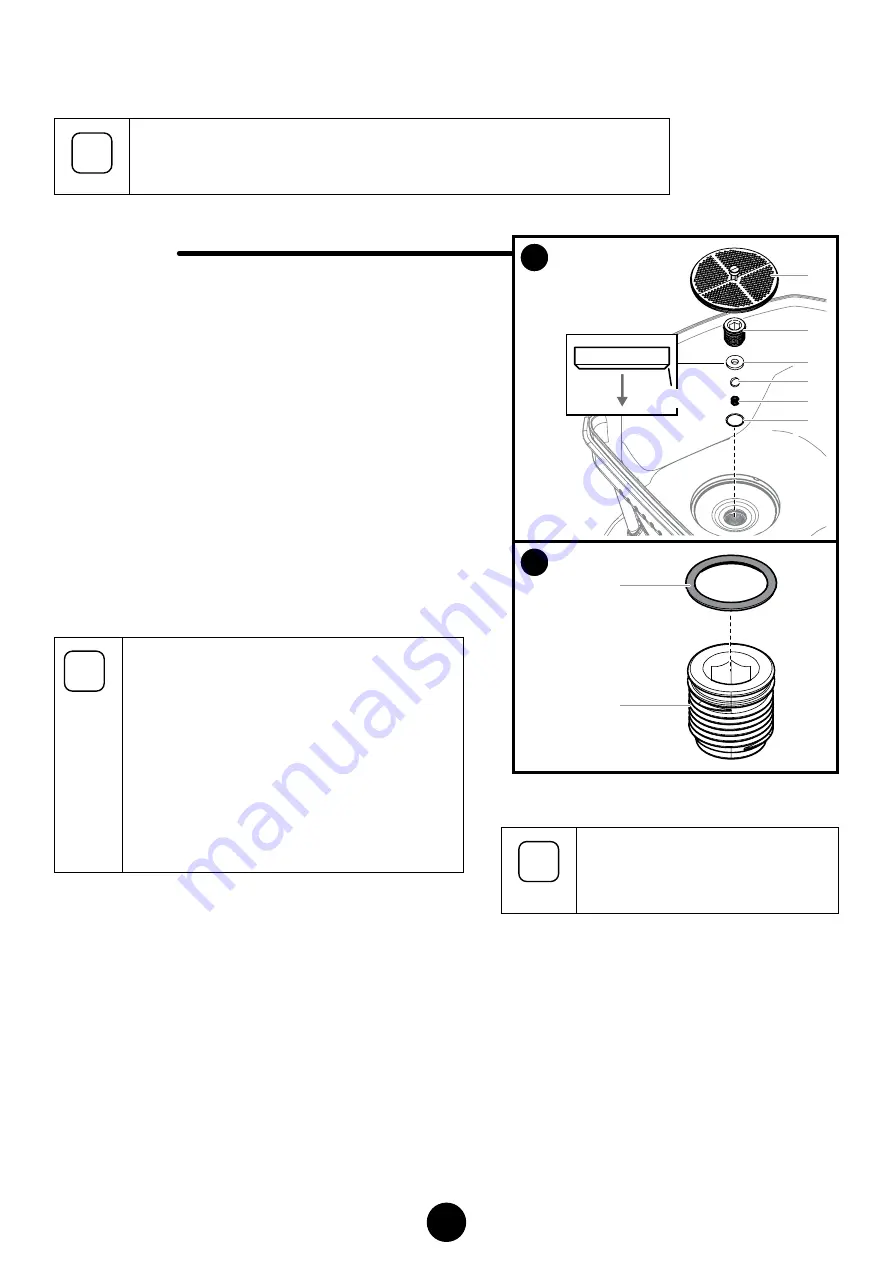

Lubricate the O-ring (7) with penetrating oil (WD40) and install onto

the inlet fitting (8). Lubricate the O-ring (7) once more after it is

installed on the inlet fitting.

3.

Replace all parts back into the inlet valve housing in the reverse order

of how they were removed.

Note the correct orientation of the inlet valve seat (3). The taper

should be facing downward upon reinstallation.

Replace inlet valve fitting (2) by screwing it into the sprayer. Tighten

securely with a 8mm (5/16”) hex wrench. Torque to 50-57 in. lbs (5.5

- 6.5 N.m). Do not overtighten the inlet valve fitting.

Replace inlet filter (1).

i

If priming problems persist, you may need

to replace the inlet valve assembly. Call

Technical Service (1-800-328-8251) to

order a new inlet valve assembly.