EN

3

IMPORTANT SAFETY INFORMATION

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with a

cord having a grounding wire with an appropriate grounding plug.

The plug must be plugged into an outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

WARNING - Improper installation of the grounding

plug can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not

connect the green grounding wire to either flat blade terminal. The

wire with insulation having a green outer surface with or without

yellow stripes is the grounding wire and must be connected to the

grounding pin.

Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt

as to whether the product is properly grounded. Do not modify the

plug provided. If the plug will not fit the outlet, have the proper

outlet installed by a qualified electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. Make

sure that the product is connected to an outlet having the same

configuration as the plug. No adapter should be used with this

product.

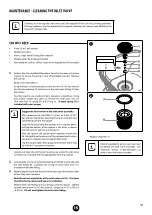

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

Attention

When the sprayer is used with a generator or

uncontrolled line voltage, the use of Wagner’s “Line

Surge Protector” (P/N 800-935) is recommended.

i

Make sure to check for grounding continuity after

service is performed on any electrical components.

Use an ohmmeter to determine that there is

continuity between accessible dead-metal parts

of the product and the grounding blade of the

attachment plug.

IMPORTANT ELECTRICAL INFORMATION

Attention

Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will

accept the plug on the product.

Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

A 14 or 12 gauge cord is recommended (see chart). If an extension

cord is to be used outdoors, it must be marked with “SJW” or “SJTW”.

For example, a designation of SJTW would indicate that the cord

would be appropriate for outdoor use.

Cord gauge

Maximum cord length

12

150 feet

14

100 feet

Wagner accessory extension cords recommended:

P/N 0090241

20 foot extension cord

P/N 0090242

35 foot extension cord

SAFETY HAZARDS

WARNING: INJECTION INJURY

A high pressure paint stream produced by this

equipment can pierce the skin and underlying

tissues, leading to serious injury and possible

amputation. See a physician immediately.

PREVENTION:

•

Do not aim the gun at, or spray any person or animal.

•

Keep hands and other body parts away from the discharge. For

example, do not try to stop leaks with any part of the body.

•

NEVER put your hand in front of the gun. Gloves will not provide

protection against an injection injury.

•

ALWAYS keep the tip guard in place while spraying. The tip

guard provides some protection but is mainly a warning device.

•

Only use a nozzle tip specified by the manufacturer.

•

Use caution when cleaning and changing nozzle tips. In the case

where the nozzle tip clogs while spraying, ALWAYS lock gun

trigger, shut pump off, and release all pressure before servicing,

cleaning tip or guard, or changing tip. Pressure will not be

released by turning off the motor. The PRIME/SPRAY valve

or pressure bleed valve must be turned to their appropriate

positions to relieve system pressure. Refer to PRESSURE RELIEF

PROCEDURE described in the pump manual (page 7).

•

Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn off the unit and

relieve the pressure in accordance with the manufacturer’s

instructions.