EN

5

IMPORTANT SAFETY INFORMATION

GENERAL INFORMATION

WARNING: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials

can be harmful if inhaled or come in contact

with the body. Vapors can cause severe nausea,

fainting, or poisoning.

PREVENTION:

•

Use a respirator or mask if vapors can be inhaled. Read all

instructions supplied with the mask to be sure it will provide the

necessary protection.

•

Wear protective eyewear.

•

Wear protective clothing as required by coating manufacturer.

WARNING: GENERAL

Can cause severe injury or property damage.

PREVENTION:

•

Always wear appropriate gloves, eye protection, clothing and a

respirator or mask when painting.

•

Do not operate or spray near children. Keep children away from

equipment at all times.

•

Do not overreach or stand on an unstable support. Keep

effective footing and balance at all times.

•

Stay alert and watch what you are doing.

•

Do not operate the unit when fatigued or under the influence of

drugs or alcohol.

•

Do not kink or over-bend the hose. Airless hose can develop

leaks from wear, kinking and abuse. A leak can inject material

into the skin.

•

Do not expose the hose to temperatures or pressures in excess

of those specified by manufacturer.

•

Do not use the hose as a strength member to pull or lift the

equipment.

•

Use lowest possible pressure to flush equipment.

•

Follow all appropriate local, state and national codes governing

ventilation, fire prevention and operation.

•

The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act

(OSHA). These standards, particularly part 1910 of the General

Standards and part 1926 of the Construction Standards should

be consulted.

•

Before each use, check all hoses for cuts, leaks, abrasion or

bulging of cover. Check for damage or movement of couplings.

Immediately replace hose if any of those conditions exist. Never

repair a paint hose. Replace with a conductive high-pressure

hose.

•

Do not spray outdoors on windy days.

•

Always unplug cord from outlet before working on equipment

(electric models only).

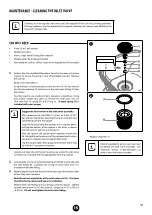

SPECIFICATIONS

Control Pro 130 Power Tank

Maximum Pressure

1600 PSI (11.1 MPa)

Capacity

0.24 GPM (0.91 LPM)

Tank Capacity

1.5 gallon (5.7 l)

Horsepower

0.38

Max. tip

0.015”

Power Requirement

15 amp minimum circuit on 115 VAC,

60 Hz current

Generator power

requirement

2500 Watt (disable idle-down feature)

Overheating

protection

This sprayer has a built-in protective

device to prevent damage from

overheating. The sprayer may

automatically shut down after heavy

use. If this happens, turn switch OFF

(0), unplug the sprayer and allow to

cool for 20-30 minutes and resume

spraying.

CAPABILITY

Sprays a variety of paints (oil-based and latex), primers, stains,

preservatives and other nonabrasive materials.

DO NOT USE!

This pump should not be used with textured materials, block filler,

lacquers, industrial enamels, or asphalt sealer or materials containing

HHC. See coating supplier if flash point is not listed on the container.

Do not spray or clean with liquids having a flash point of less than

38ºC (100ºF). Flash point is the temperature at which a fluid can

produce enough vapor to ignite.

SAFETY FEATURES

Spray gun trigger lock and pressure diffuser; built-in tip safety guard;

PRIME/SPRAY knob for safe pressure release. Conforms to UL STD

1450. Certified to CSA C22.2 NO 68.