26

Control Pro 250 M

GB

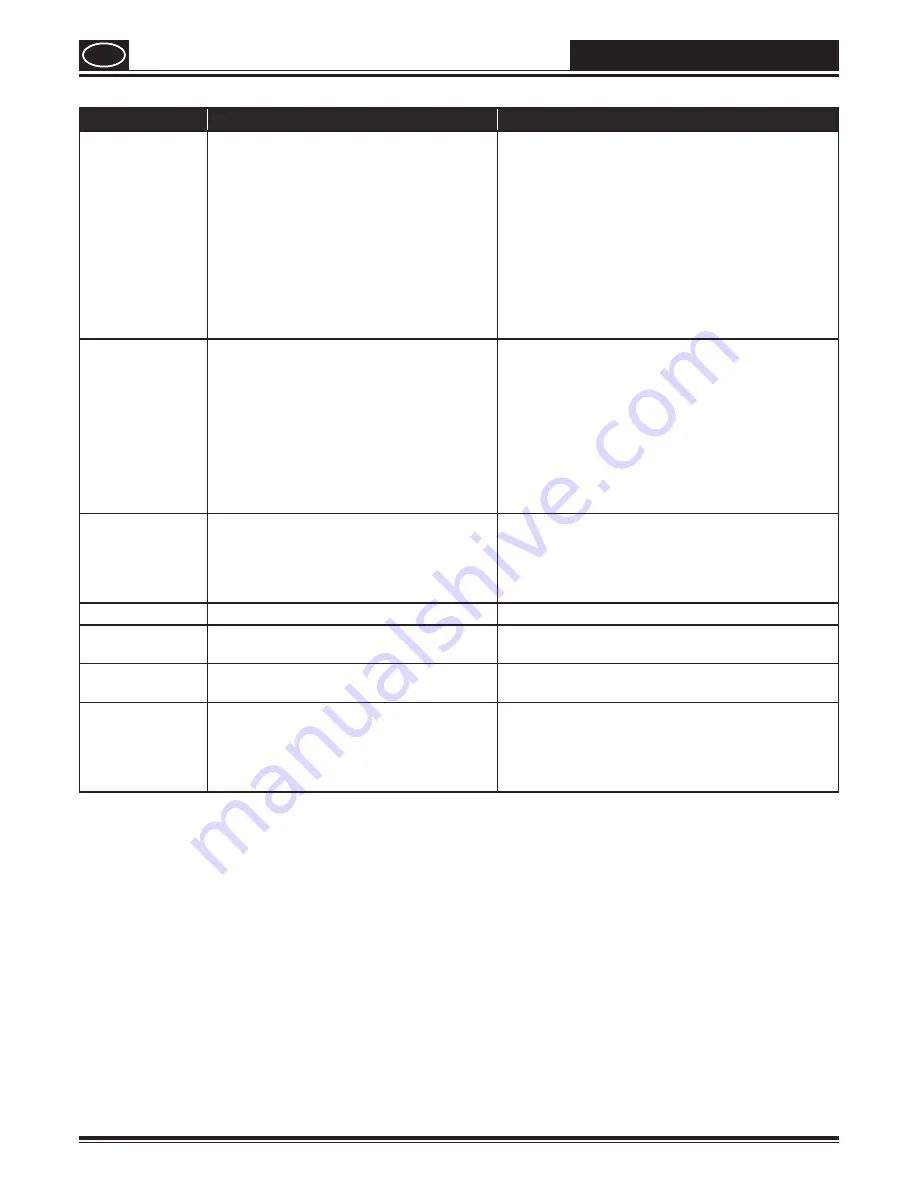

Correction of Malfunctions

Problem

Cause

Remedy

The sprayer does

not start.

•

The sprayer is not plugged in.

•

The device is switched off.

•

The sprayer was turned off while still under

pressure.

•

No voltage is coming from the wall plug.

•

The extension cord is damaged or has too low

a capacity.

•

Device overheated

•

There is a problem with the motor.

➞

Plug the sprayer in.

➞

Turn the ON/OFF switch to ON (I).

➞

Perform pressure relief procedure and set selector

switch back to SPRAY

➞

Properly test the power supply voltage.

➞

Replace the extension cord.

➞

Switch the device off, turn the selector switch to the

PRIME position (vertical), remove the mains plug and

allow device to cool down for min. 30 minutes. Eliminate

the cause of overheating, e.g. covered ventilation slot.

➞

Please contact Wagner Service

The spray device

runs but does not

suck up any paint

when the selector

switch is set to the

PRIME position.

•

The unit will not prime properly or has lost

prime.

•

The paint bucket is empty or the suction tube

is not totally immersed in the paint.

•

The suction tube is clogged.

•

The suction tube is loose at the inlet valve.

•

The inlet valve is stuck.

•

The inlet valve is worn or damaged.

•

The PRIME/SPRAY valve is plugged

➞

Try to prime the unit again.

➞

Refill the bucket or immerse the suction tube in

paint.

➞

Clean the suction tube.

➞

Tighten it securely.

➞

Press the inlet valve pusher. If the problem is not

solved, clean the inlet valve.

➞

Replace

➞

Please contact Wagner Service

The sprayer draws

up paint but the

pressure drops

when the gun is

triggered.

•

The spray nozzle is worn.

•

The inlet filter is clogged.

•

The paint is too viscous or contaminated.

•

The inlet valve is worn or damaged.

➞

Replace the spray nozzle with a new nozzle.

➞

Clean the inlet filter.

➞

Thin or strain the paint.

➞

Replace

The spray gun leaks

•

Internal parts of the gun are worn or dirty.

➞

Please contact Wagner Service

The nozzle

assembly leaks

•

The nozzle was assembled incorrectly.

•

A seal is dirty.

➞

Check the tip assembly and assemble properly

➞

Clean the seal.

The spray gun will

not spray.

•

The spray nozzle is plugged.

•

The spray tip is in the reverse position.

➞

Clean the spray nozzle.

➞

Put the nozzle in the forward position.

The paint pattern is

tailing.

•

The paint is too viscous or contaminated.

•

The spray nozzle is plugged.

•

The spray nozzle is worn.

•

The inlet filter is clogged.

•

The inlet valve is worn or damaged.

➞

Thin or strain the paint.

➞

Clean the spray nozzle.

➞

Replace the spray nozzle with a new nozzle.

➞

Clean the inlet filter.

➞

Replace