28

Control Pro 250 M

GB

Warning

If the supply cord of this appliance is damaged, it must only be

replaced by a repair shop appointed by the manufacturer, because

special purpose tools are required.

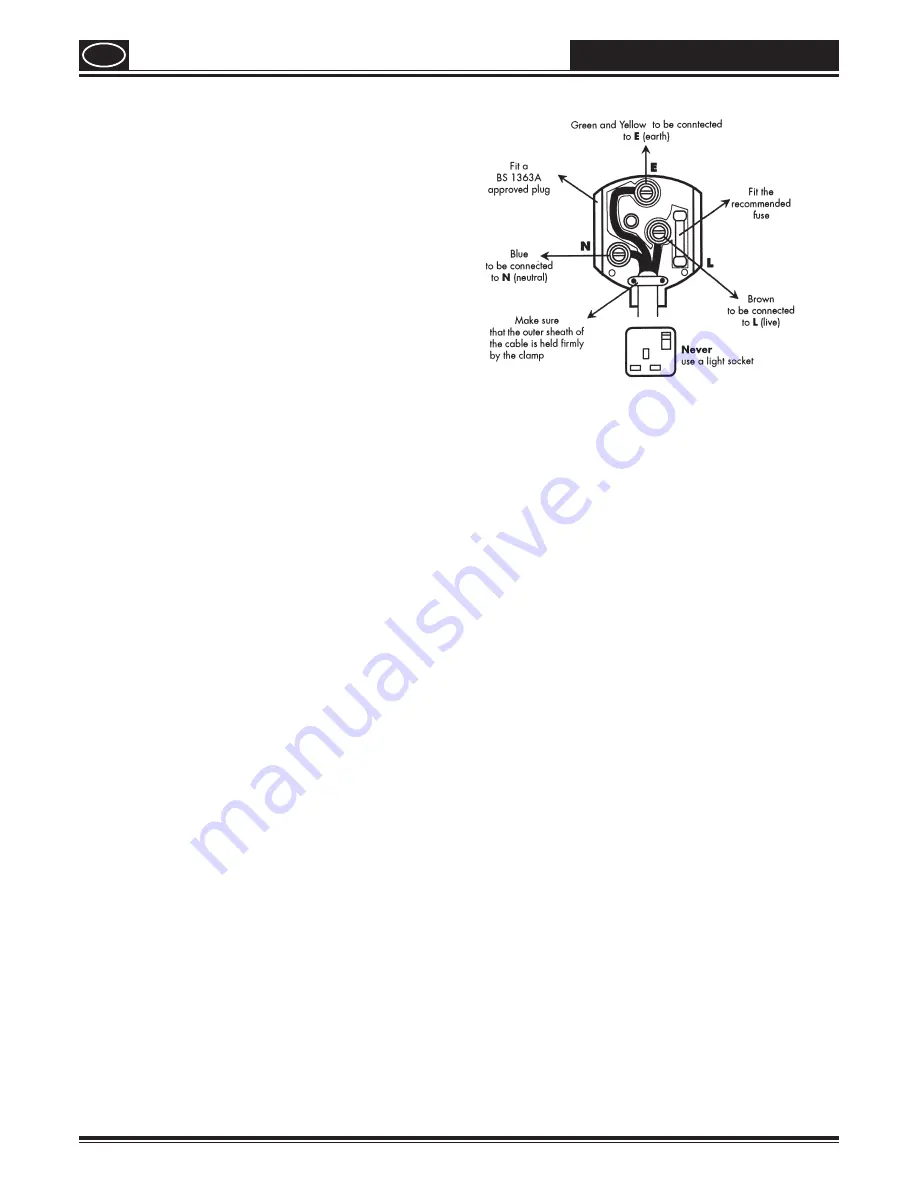

The wires in this mains lead are coloured in accordance with the

following code:

green/yellow

=

earth

blue

=

neutral

brown

=

live

As the colours of the wires in the mains lead of this appliance may not

correspond with the coloured markings identifiying the terminals in

your plug, proceed as follows:

•

The wire which is coloured green and yellow must be connected

to the terminal in the plug which is marked with the letter E or by

the earth symbol or coloured green or green and yellow.

•

The wire which is coloured blue must be connected to the

terminal which is marked with the letter N or coloured black.

•

The wire which is coloured brown must be connected to the terminal which is marked with the letter L or coloured brown.

•

Should the moulded plug have to be replaced, never re-use the defective plug or attempt to plug it into a different 13 A socket.

This could result in an electric shock.

•

Should it be necessary to exchange the fuse in the plug only use fuses approved by ASTA in accordance with BS 1362. Only 13

Amp fuses may be used.

•

To ensure that the fuse and fuse carrier are correctly mounted please observe the provided markings or colour coding in the

plug.

•

After changing the fuse, always make sure that the fuse carrier is correctly inserted. With out the fuse carrier, it is not permissible

to use the plug.

•

The correct fuses and fuse carriers are available from your local electrical supplies stockist.