20

Control Pro 350 Extra Skid

GB

Do not put the high-pressure hose into solvents. Use only a wet cloth to wipe down the outside of the hose.

Lay the high-pressure hose in such a way as to ensure that it cannot be tripped over.

Electrostatic charging of spray guns and the high-pressure hose is discharged through the high-pressure hose. For this reason the

electric resistance between the connections of the high-pressure hose must be equal or lower than 197 kΩ/m (60 kΩ/ft.).

i

For reasons of function, safety and durability, only use genuine WAGNER high-pressure hoses and spray

nozzles. For overview see „Spare parts lists“.

i

The risk of damage rises with the age of the high-pressure hose.

Wagner recommends replacing high-pressure hoses after 6 years.

Connecting the device

A properly earthed socket outlet with earthing contact must be used for connection. The connection must be equipped

with a residual current protective device with INF ≤ 30 mA.

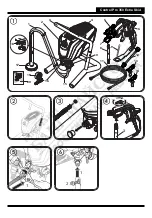

Setting up the unit

Danger

When working indoors:

Vapors containing solvents may not be allowed to build up in the area of the device.

Setting up the unit on the side a way from the sprayed object.

A minimum distance of 5 m between the unit and spray gun is to be maintained.

When working outdoors:

Vapors containing solvents may not be allowed to blow toward the unit.

Note the direction of the wind.

Set the unit up in such a way that vapors containing solvents do not reach the unit and build up there.

A minimum distance of 5 m between the unit and spray gun is to be maintained.

Maintenance and repairs

Danger

Before carrying out any work on the device, relieve the pressure and unplug the power plug from the socket.

Cleaning the unit

Danger

Danger of short circuit through penetrating water!

Never spray down the unit with high-pressure or high-pressure steam cleaners.

Cleaning units with solvents

Danger

When cleaning the unit with solvents, the solvent should never be sprayed or pumped back into a container

with a small opening (bunghole). An explosive gas/air mixture can be produced. The container must be

earthed.

Do not use flammable materials for cleaning purposes.

Earthing of the object

The object to be coated must be earthed.

Thermal release

The device is equipped with a thermal release which disconnects the device in case of overheating.

In this case switch the device

off, turn the selector switch to the PRIME position (vertical), remove the mains plug and allow device to cool down for min. 30

minutes. Eliminate the cause of heating, e.g. slots for air intake covered.