22

Control Pro 350 Extra Skid

GB

Preparation of the Coating Material

Using Control Pro 350 Extra interior wall paints, varnishes and glazes can be applied by spraying without diluting them, or by

diluting them slightly. Detailed information is available in the technical data sheet of the manufacturer (

Æ

Internet download).

1. Stir the material thoroughly and dilute it in the container as per the recommended dilution (an agitator is recommended for

stirring).

Thinning recommendation

Sprayed material

Glazes

undiluted

Wood preservatives containing solvents or based on water, mordants, oils, disinfection agents, plant

protective agents

undiluted

Paints containing solvents and watersoluble paints, primers, vehicle coating paints, thick-film glazes

dilute by 5 - 10 %

Interior wall paint (dispersions and latex paint)

dilute by 0-10 %

i

The values in the table are reference values.

Find out how much the paint needs to be thinned by testing it. Details on how to test the spray paint can be found

in the section called "Spray Technique".

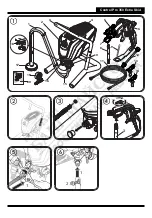

Assembly

1. Place both doors / flaps in the storage compartment.

2. Insert the handle as shown in the picture and secure it by pushing downwards. (Fig. 2)

3. Remove the protective covers on the hose and hose connection. (Fig. 3)

4. Place the spray gun against the tapered end of the hose (Fig. 4, 1) and twist the gun onto the hose. Firmly tighten the thread

using a wrench (13).

Danger

To check whether or not the hose is pressurized, the provided pressure gauge has to be secured to the high-

pressure hose.

5. Screw the pressure gauge to the hose connection.

6. Screw the high pressure hose onto the pressure gauge.

Using a wrench (16), hold the hose connection firmly and tighten the hose with another wrench (17). (Fig. 5)

7. Slide the suction hose onto the inlet valve. Secure with the clamp. (Fig. 6)

8. Press the return hose onto the return hose fitting. Secure with the clamp. (Fig. 7)

Control elements on the device (Fig. 8)

A

The pressure of the spray is set by the pressure regulator.

The correct spray pressure depends on the paint being used.

The device is switched off if the pressure regulator is in position 0.

B

The following settings can be made with the selector switch:

PRIME (Switch set vertically)

Æ

•

For prefilling the system with paint

•

For pressure relief

SPRAY (Switch set horizontally)

Æ

•

For using the spray gun

Spray Gun

Danger

Always lock the trigger off when attaching the spray nozzle or when the spray gun is not in use.

•

Fold the trigger lock downwards to lock the trigger (Fig. 9, A).

•

Fold the trigger lock upwards to unlock the trigger (Fig. 9, B).

i

Another nozzle size and gun filter must be used, depending on the material to be processed.

Thin materials:

Nozzle 311

Æ

Filter red

Thick materials:

Nozzle 515/619

Æ

Filter white