25

Control Pro 350 Extra Skid

GB

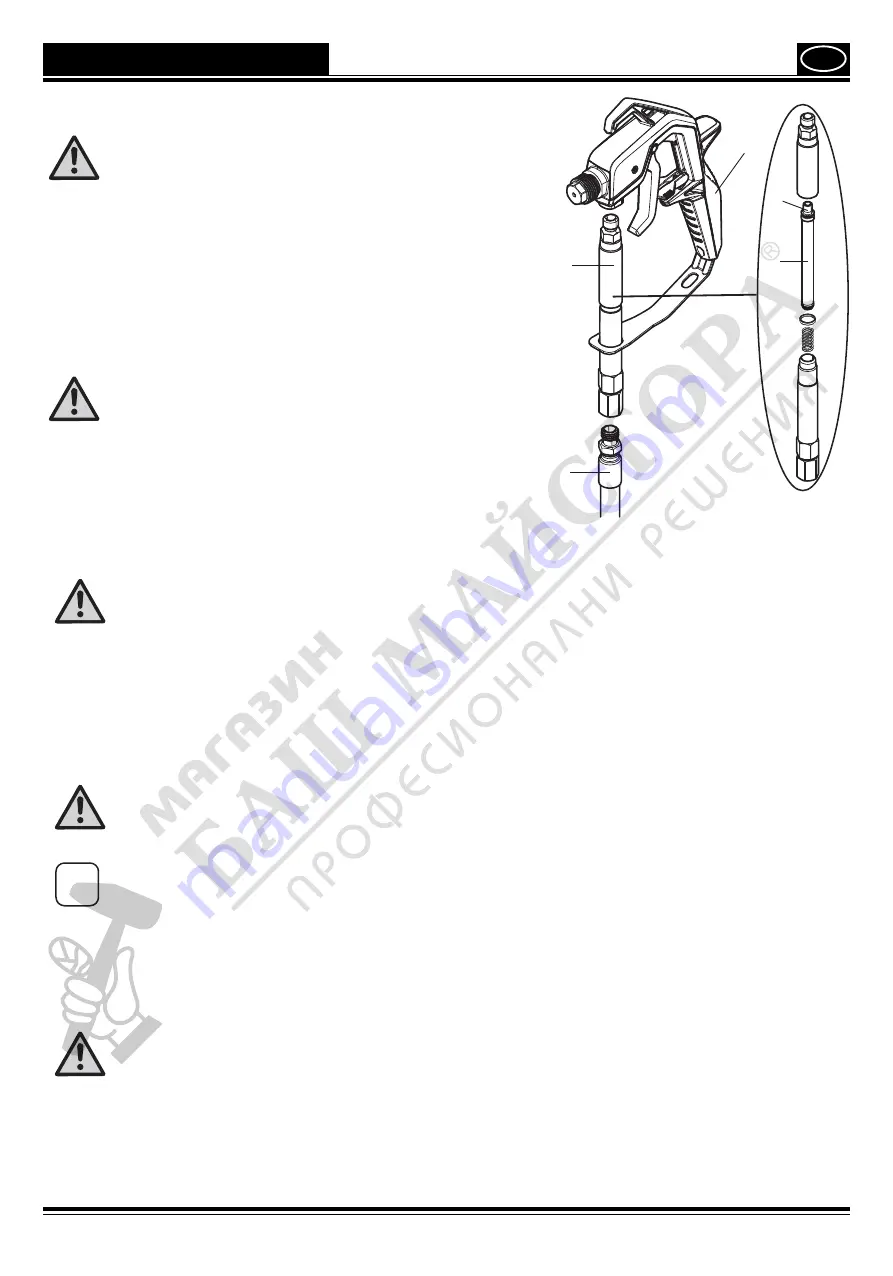

HEA Filter Set

Assembly

Danger

The gun and high-pressure hose must be de-pressurised before

the filter set is installed / removed.

1. Disconnect the high-pressure hose from the gun (1).

2. If necessary, screw on the filter housing (2) and insert a filter (3) appropriate

to the nozzle (the conical side (A) must point upwards).

Nozzle 311

Æ

Filter red

Nozzle 517 / 619

Æ

Filter white (pre-installed in the filter housing)

3. Screw the filter housing (2) to the gun (1).

4. Screw the high-pressure hose (4) firmly to the filter housing (2).

Cleaning

Danger

The gun and high-pressure hose must be de-pressurised before

the filter set is installed / removed.

1. Remove the filter housing (2) from the hose (4) and the gun (1).

2. Screw on the filter housing (2) and remove the filter (3).

3. Thoroughly clean the filter (3) and filter housing (2) (if worn, replace the filter).

4. During reassembly, take care not to lose the seal and spring.

Interruption of Work

Danger

Be sure to follow the Pressure Relief Procedure when shutting the unit off for any purpose.

This procedure relieves the pressure from the spray hose and the gun. Watch the pressure gauge ––> 0 bar

•

Switch the device off (pressure regulator in position 0) and remove the power plug.

•

Put the spray gun in a plastic bag and seal so that it is air-tight.

•

Wet paint surface in paint container with a little water to prevent a skin from forming.

Taking Out of Operation and Cleaning

Proper cleaning is the prerequisite for problem-free operation of the paint application device. No warranty claims are accepted

in case of improper or no cleaning.

Danger

Do not use flammable materials / cellulose thinner for cleaning purposes.

i

Always clean the device as soon as you have finished operation.

Dried-on coating substance makes cleaning more difficult.

1.

Perform Pressure Relief Procedure.

2.

Secure the spray gun.

3. Remove the nozzle holder from the spray gun. (Fig. 19)

4. Put the suction hose and return flow pipe into a container full of water or suitable cleaning solution.

5. Turn the switch to the SPRAY position and set maximum pressure.

6. Hold the spray gun on the edge of the paint container. (Fig. 20)

Danger

Ground gun with a metal container if flushing with solvent.

7. Unlock the spray gun and pull the trigger to pump the excess paint out of the system into the paint container. Release the trigger again as

soon as the cleaning agent comes out.

8. Turn the switch into the PRIME position (vertical).

9. Hold the spray gun on the edge of the cleaning container.

10. Pull the trigger and hold it until only clear liquid comes out.

3

1

2

4

A