19

Control Pro 350 Extra Skid

GB

Explosion protection

Danger

Do not use the unit in work places which are covered to the explosion protection regulations.

Danger of explosion and fire through sources of flame during spraying work

Danger

There may be no sources of flame such as, for example, open fires, smoking of cigarettes, cigars or tobacco

pipes, sparks, glowing wires, hot surfaces, etc. in the vicinity.

Electrostatic charging (formation of sparks or flame)

Danger

Under certain circumstances, electrostatic charging can occur on the unit due to the rate of flow of the

coating material when spraying. On discharging this can result in the emergence of sparks or fire. It is

therefore necessary that the unit is always earthed through the electrical installation. The connection must

take place through a correctly earthed two-pole-and-earth socket outlet.

Ventilation

Good natural or artificial ventilation must be ensured in order to avoid the risk of explosion or fire and damage to health during

spray work.

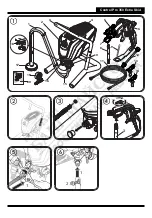

Secure device and spray gun

All hoses, fittings, and filter parts must be secured before operating spray pump. Unsecured parts can eject at great force

or leak a high pressure fluid stream causing severe injury.

Always secure the spray gun when mounting or dismounting the nozzle and in case of interruption to work.

Recoil of spray gun

Danger

In case of high operating pressure, pulling the trigger can effect a recoil force of up to 15 N.

If you are not prepared for this, your hand can be thrust backwards or your balance lost. This can lead to

injury.

Continuous stress from this recoil can cause permanent damage to health.

Max. operating pressure

Max. permissible operating pressure for spray gun, spray gun accessories and high-pressure hose may not fall short of

the maximum operating pressure of 110 bar (11 MPa) stated on the unit.

Coating substance

Caution against dangers that can arise from the sprayed substance and observe the text and information on the containers or the

specifications given by the substance manufacturer.

Do not spray any liquid of unknown hazard potential.

High-pressure hose (safety note)

Danger

Attention, danger of injury by injection! Wear and tear and kinks as well as usage that is not appropriate to

the purpose of the device can cause leakages to form in the high-pressure hose. Liquid can be injected into

the skin through a leakage.

High-pressure hoses must be checked thoroughly before they are used.

Replace any damaged high-pressure hose immediately.

Never repair defective high-pressure hoses yourself!

Avoid sharp bends and folds: the smallest bending radius is about 20 cm.

Do not drive over the high-pressure hose. Protect against sharp objects and edges.

Never pull on the high-pressure hose to move the device.

Do not twist the high-pressure hose.