13

ENGLISH

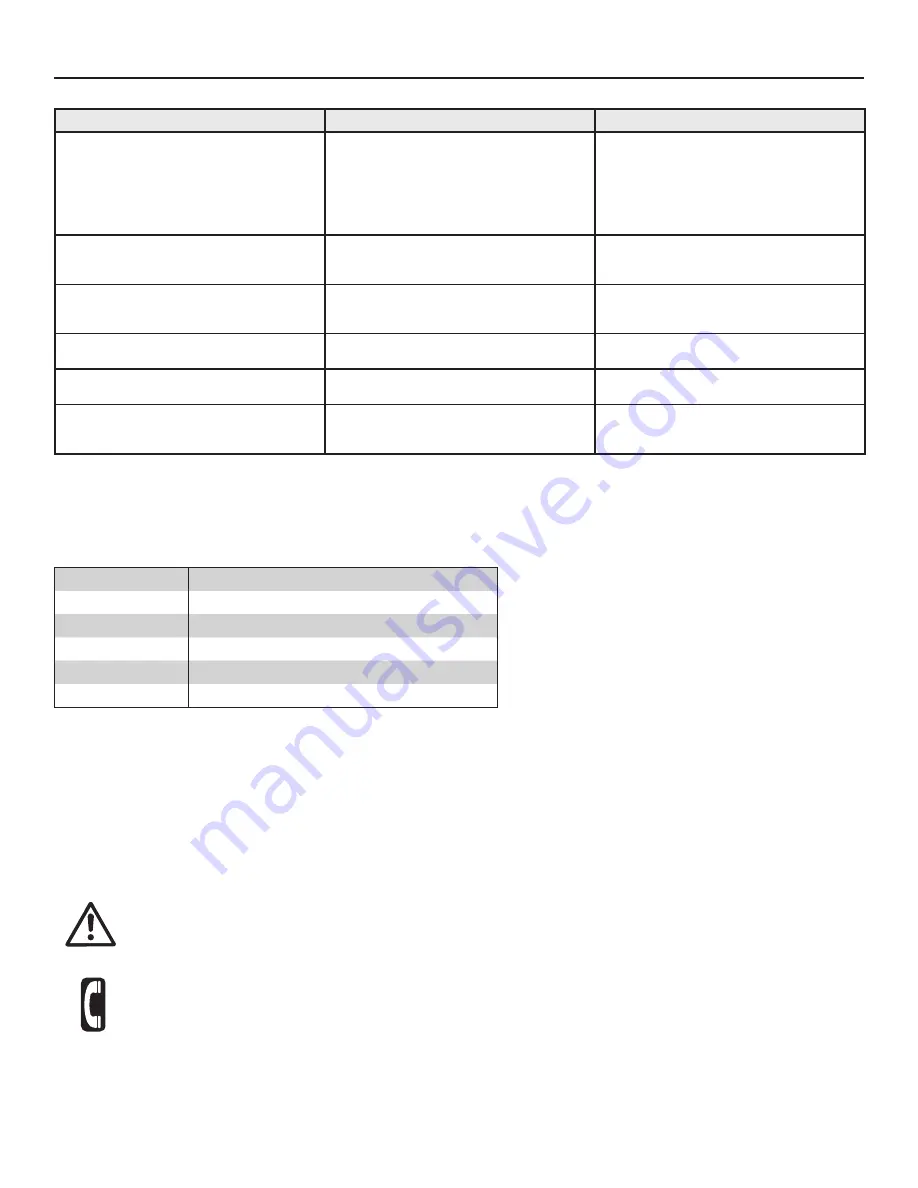

TROUBLESHOOTING

PROBLEM

CAUSE

SOLUTION

Problem A: Little or no material flow

1. Nozzle clogged.

2. Suction tube clogged.

3. Material flow setting too low.

4. No pressure build up in container.

5. Air filter clogged.

6. Spray material too thick.

1. Clean.

2. Clean.

3. Increase material flow setting.

4. Tighten container or container lid and

check the clear tube.

5. Change

6. Thin.

Problem B: Material leaking

1. Nozzle loose.

2. Nozzle worn.

3. Material build-up on air cap and nozzle.

1. Tighten.

2. Replace.

3. Clean.

Problem C: Spray pattern too thick, runs

and sags

1. Material flow setting too high.

2. Applying too much material.

1. Decrease material flow setting.

2. Adjust material flow or increase movement

of spray gun.

Problem D: Spray nozzle spits

1. Material in container running out.

2. Air filter clogged.

1. Refill.

2. Change.

Problem E: Too much overspray

1. Gun too far from spray object.

2. Material flow setting too high.

1. Reduce distance (6”-8” is ideal).

2. Decrease the material flow.

Problem F: Pattern is very light and

splotchy

1. Moving the spray gun too fast.

2. Material flow setting too low.

1. Adjust material flow or decrease

movement of spray gun.

2. Increase material flow setting.

This unit contains no servicable electrical parts. Do not attempt to

service yourself. Store indoors with the cord wrapped around the

turbine handle.

Have you tried the recommendations above and are still having

problems? In the United States, to speak to a customer service

representative, call our Technical Service at 1-888-783-2612.

OPTIONAL EXTRAS

Needles and fluid tips of different sizes can be obtained as sets under the following accessory numbers. Please call our toll free helpline

to order these at 888-783-2612.

Part No.

Description

0HV5ACC10US

1.0mm dia fluid tip, needle & seal

0HV5ACC15USR

1.5mm dia fluid tip, needle & seal

0HV5ACC20USR

2.0mm dia fluid tip, needle & seal

0HV5ACC25USR

2.5mm dia fluid tip, needle & seal

0L0190A

Material container, solvent based materials*

*The PTFE coating inside the material container included with the sprayer is meant for water-based materials. For solvent based

materials, especially lacquers, order cup part number 0L0190A for a non-coated material container.