39

ENGLISH • FRANÇAIS • ESPAÑOL

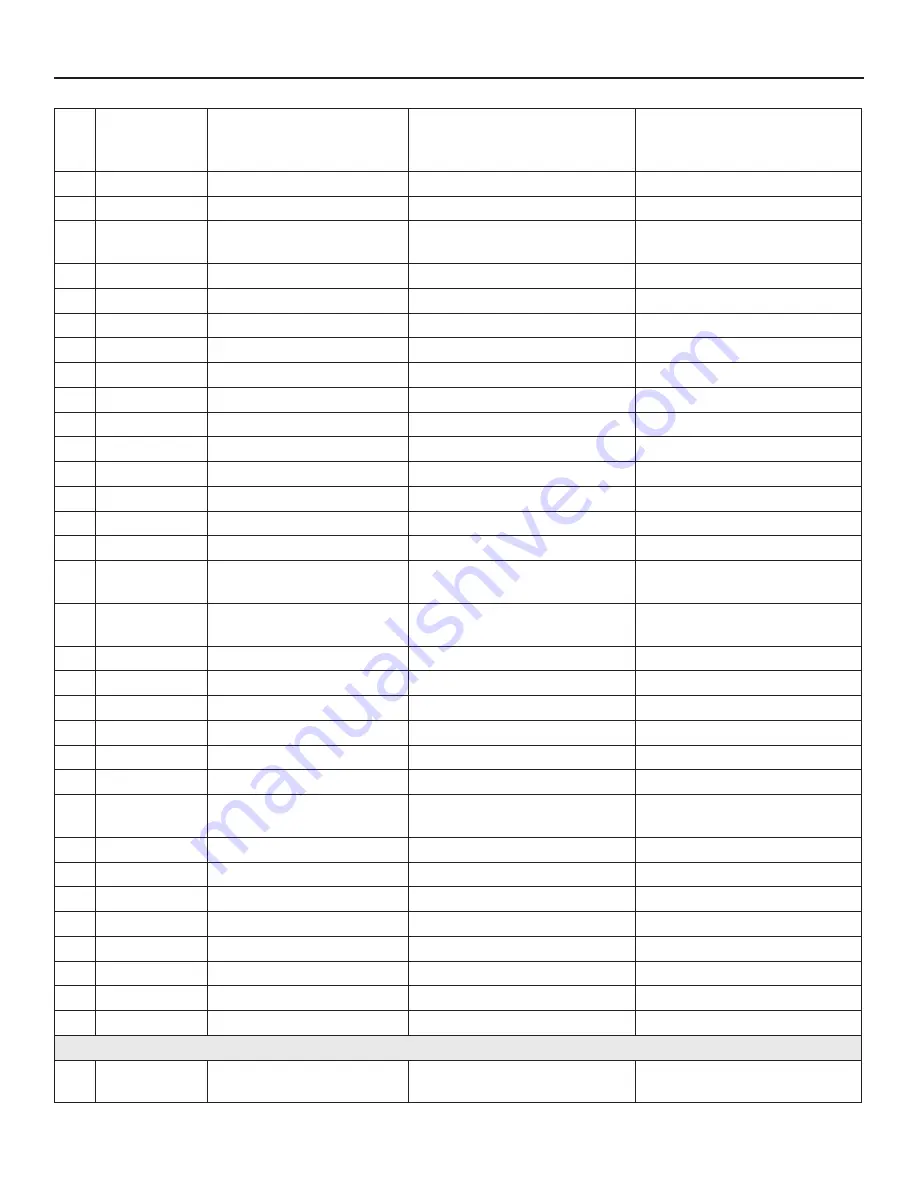

PARTS LIST • LISTE DE PIÈCES • LISTA DE PIEZAS

#

Part No.

N˚ de piéce

Pieza No.

English

Description

Français

Description

Español

Descripción

1

L0151

Air Cap Ring

Anneau du chapeau d’air

Anillo del soporte de la boquilla

2

2354029

Air Cap

Chapeau d’air

Soporte de la boquilla de aire

3

L0162

Air Distributor Plate

Assemblage disque d’orientation

du jet

Placa del distribuidor de aire

4*

-------

Fluid Tip, 1.5 mm

Buse 1,5mm

Boquilla de 1.5mm

5*

2354077

Fluid Tip Seal

Joint buse

Sello de la boquilla

6

L0179

Pivot Screw

Vis axe

Tornillo pivote

7

L0195

Washer

Rondelle

Arandela

8

-------

Main Body

Assemblage partie principale

Ensamblaje del cuerpo principal

9*

-------

Fluid Needle 1.5 mm

Pointeau 1,50mm

Aguja del fluido de 1.5mm

10

-------

Adaptor

Adaptateur

Adaptador

11

2353978

Spring

Ressort

Muelle

12

L0176

Fluid Adjusting Screw

Vis de réglage

Tornillo de ajuste

13

L0178

Pivot

Axe

Pivote

14

2353984

Air Feed Tube

Tube plongeur

Tubo de alimentación de aire

15

L0173

Gland Nut

Écrou de garniture

Tuerca del prensaestopas

16

2354010

Gland Washer (3 pcs)

Rondelle d’écrou de garniture (3

pièces)

Arandela del prensaestopas (3

piezas)

17

2353992

Paint Container (water based

coatings)

Réservoir de peinture (matériaux à

base d’eau)

Contenedor de pintura (materiales

a base de agua)

18

L0189

Centre Bolt Nut

Écrou de boulon central

Tuerca de perno central

19

2353989

Gasket

Joint d’étanchéité

Junta

20

L0187

Lid

Assemblage couvercle

Ensamblaje de la tapa

21

L0186

Shim

Cale

Arandela de separación

22

L0185

Clamp Lever

Levier de serrage

Palanca de sujeción

23

L0184

Yoke

Fourche

Boca de enganche

24

2354161

Centre Bolt & Pick-Up Tube

Assemblage écrou central et tube

plongeur

Conjunto tubo de recolección y

perno central

25

L0177

Trigger

Gâchette

Palanca de control

26

153165

Viscosity Cup

Godet de viscosité

Depósito de viscosidad

27

L0191

Wrench

Clé

Llave de tornillos

28

2314523

Air hose

Tuyau d’air

Manguera de aire

29

V0710

Hose adapter

Adaptateur de tuyau d’air

Adaptador de manguera de aire

30

-------

Turbine (includes item 31)

Turbine (inclut de pièce 31)

Turbina (incluye le articulo 31)

31

V0377

Filter

Filter

Filtro

32

514209

Cleaning brush

Brosse de nettoyage

Cepillo de limpieza

*

0HV5ACC15USR 1.5mm dia fluid tip, needle &

seal

Buse, pointeau et joint Ø 1.5mm

Aguja, sello y boquilla de fluido,

1.5mm diám.