8

ENGLISH

SPRAYER

CONTROLS

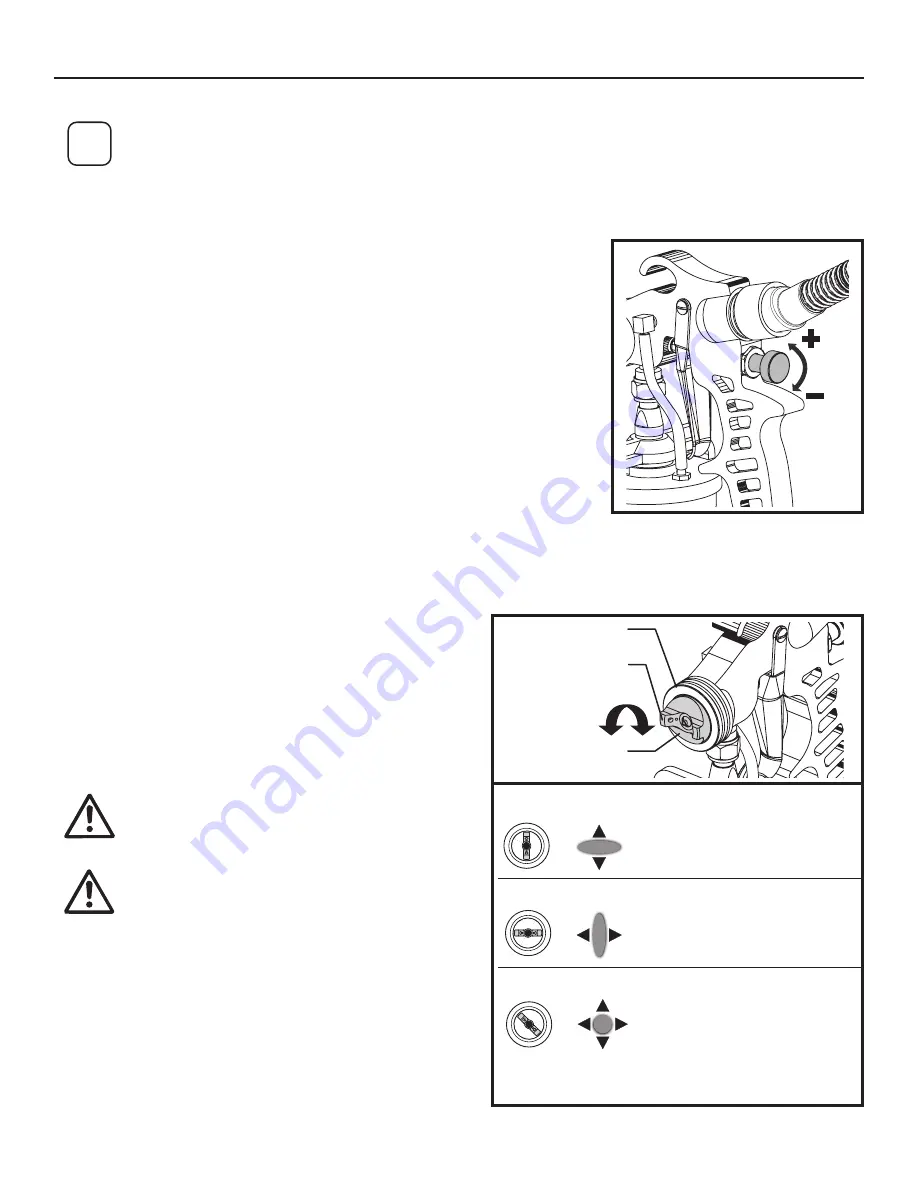

MATERIAL FLOW CONTROL

The material flow control determines the amount of material that is sprayed from the

spray gun.

Set the material flow by turning the knob on the rear of the spray gun.

•

For thicker materials, it is recommended that you start with the highest material

flow setting and then gradually decrease the flow to suit your particular spraying

needs.

•

For thinner materials, it is recommended that you start with a low material flow

setting, and then gradually increase the flow to suit your particular spraying needs.

•

The higher the flow setting, the quicker you will have to work in order to avoid drips

and sags in your spray pattern.

Tip: Spraying with the control set too high will result in a spray pattern that runs and

sags (too much material).

Tip: Spraying with the control set too low will result in a spray pattern that does not

cover (not enough material). Also, if the knob is loosened too much, it can fall out.

Replace by threading it back in.

ADJUST SPRAY PATTERN

Adjust the spray pattern by turning the air cap ears.

The positions of the air cap and the corresponding spray

pattern shapes are illustrated below.

Test each pattern and use whichever pattern is suitable for

your application.

NEVER trigger the gun while turning the air

cap. NEVER point the spray gun at any part of

the body.

Aenon

When changing the spray pattern, make sure

the air cap ring is not loosened.

i

Spray performance will depend upon a number of factors: material thickness, spray pattern selected, and material

flow. Testing different control settings will help you achieve the desired results. See descriptions below to help

with your project.

AIR CAP EARS

AIR CAP

AIR CAP RING

Horizontal pattern

=

=

=

Use ‘up and down’ spraying

motion

Vertical pattern

=

=

=

Use ‘side to side’ spraying

motion

Round pattern

=

Use ‘up and down’ or ‘side to

side’ spraying motion

Use lower material flow

For coating smaller areas,

corners and edges