24

FinishControl 3500

GB

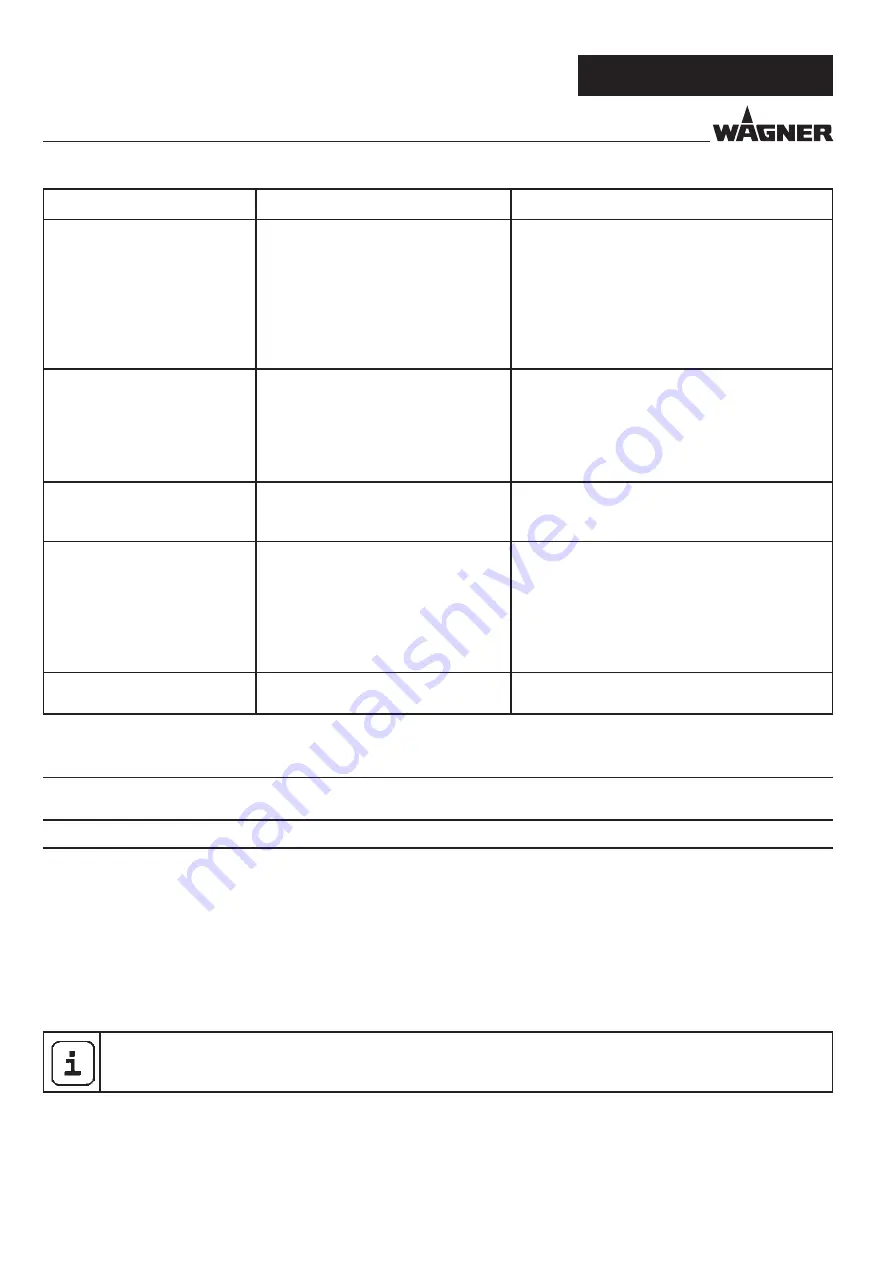

MALFUNCTION

CAUSE

REMEDY

Atomisation too coarse

•

Material volume too large

•

Nozzle contaminated

•

Viscosity of coating material too high

•

Too little pressure build-up in

container

•

Air filter heavily soiled

•

Amount of air too low

•

Air hose damaged

•

Reduce volume

•

Clean

•

Dilute further

•

Tighten container

•

Change (see section 13.1)

•

Increase volume

•

Check and replace if necessary

Spray jet pulsates

•

Coating material in container running

out

•

Nozzle seal is missing or worn

•

Air filter heavily soiled

•

Feed tube loose

•

Feed tube / feed tube filter clogged

•

Refill

•

Insert an intact nozzle seal

•

Change (see section 13.1)

•

Insert

•

Clean or use another filter

The material runs down the

object being painted

•

Too much coating material applied

•

Distance too small

•

Incorrect spray attachment

•

Reduce volume

•

Increase distance

•

Use another spray attachment

Excessive paint mist (overspray)

•

Distance to the object too large

•

Too much coating material applied

•

Amount of air too high

•

Coating substance over-diluted

•

Incorrect spray attachment

•

Incorrect spraying technique

•

Reduce distance

•

Reduce volume

•

Reduce volume

•

Reduce degree of dilution

•

Use another spray attachment

•

For information about the correct spraying

technique, please see chapter 9

Paint in the ventilating hose

•

Diaphragm soiled

•

Diaphragm defective

•

Clean the diaphragm (see section 13.2)

•

Replace the diaphragm (see section 13.2)

15

ACCESSORIES AND SPARE PARTS

15.1 ACCESSORIES

POS.

ORDER NO.

DESIGNATION

1

2321 879

StandardSpray spray attachment (yellow) (with 1000 ml container)

Processes all standard paints.

2

2321 877

FineSpray spray attachment (brown) (with 1000 ml container)

Ideal for low-viscosity paints and glazes.

3

2321 880

WallSpray spray attachment (white) (with 1400 ml container)

Designed for processing dispersions.

4

2324 749

Container with cover (1400 ml)

The FC 3500 cannot be used with the heatable TempSpray spray attachment.

ACCESSORIES AND SPARE PARTS