6

using an HVlp spray system

fc9900 Plus

3

uSing an hvlp Spray SySteM

i

Refer to the following information to operate and

understand your HVLP spray system.

i

Your system may include a short air (“whip”)

hose. The short hose should be connected to the

longer hose or a remote spraying system (sold

separately) and NOT directly to the turbine. See

your spray gun instruction manual for complete

instructions.

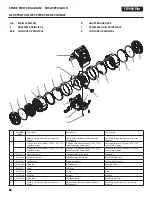

1

2

4

3

5

1.

Turbine

2.

Air hose

3.

Whip hose

4.

Coupling

5.

Spray gun

Attention

Do not attach the short air whip hose directly to

the turbine, as the hose will become damaged.

3.1

Setup

i

Use the following procedure to set up your HVLP

spray system for operation.

Keep the turbine at the maximum possible

distance from the spray area to safeguard against

explosion or fire that may be caused by sparking

electrical parts.

1.

Prepare your spray gun for operation. Refer to your spray

gun manual for material preparation, setup, and spraying

information.

2.

Attach the air hose to the air outlet on the turbine.

3.

Attach the air hose to the air inlet on your spray gun.

4.

Plug the turbine power cord into a grounded receptacle.

5.

Turn on the turbine and begin spraying.

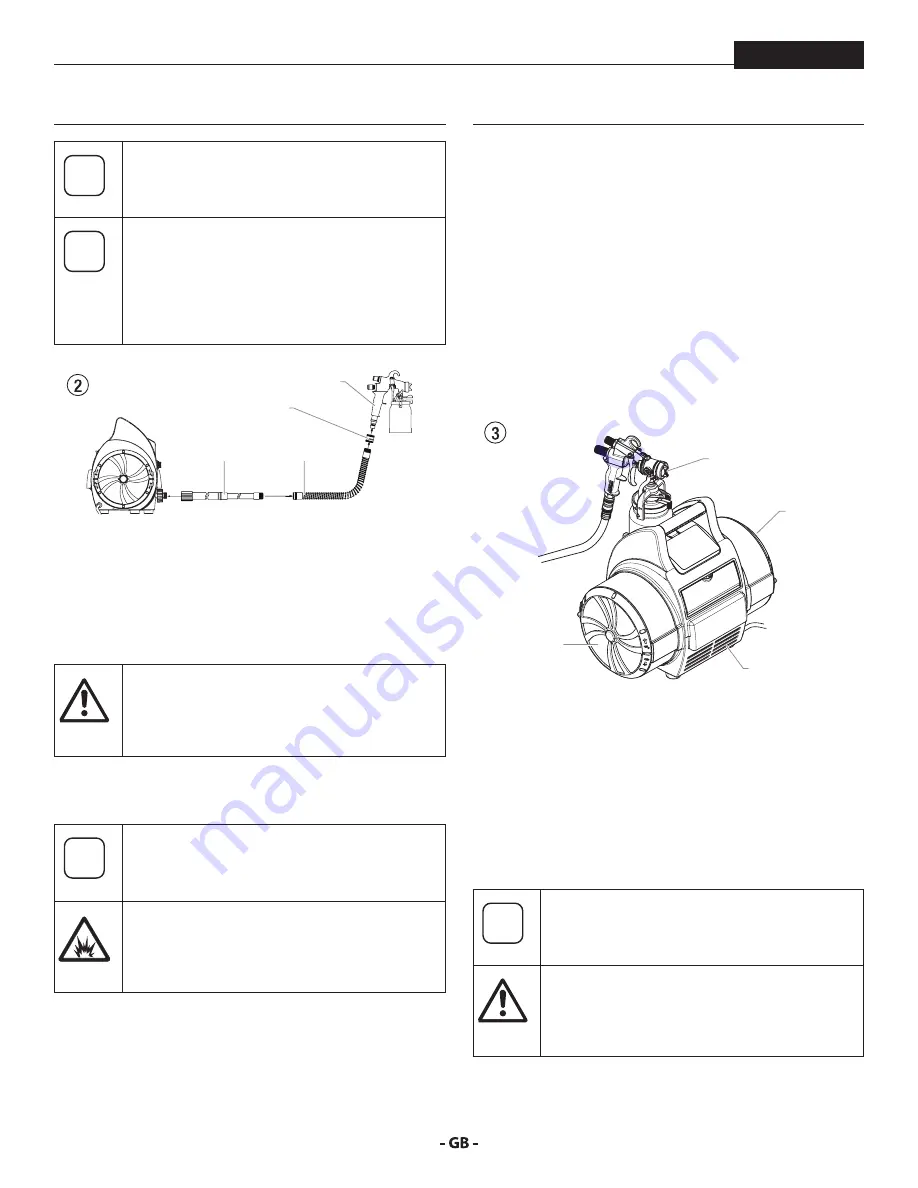

3.2

dual filtration SySteM

The turbine has two different air filters— one for atomizing air

and one for cooling air. The atomizing air filter (1) is a two-stage,

fine mesh filter designed to trap particles that may damage

your finish. The atomizing air is discharged through the nozzle

of the spray gun where it atomizes the coating material (2). The

cooling air filter (3) is a coarse mesh filter designed to allow

the proper amount of air flow through the turbine for cooling

purposes. Cooling air is exhausted through the cooling air

discharge on the front of the turbine (4).

4

3

1

2

3.3

filter warning SySteM

The filter warning system on your turbine consists of a red filter

warning light on the front control panel and an air flow switch

inside the turbine. When the air flow switch does not detect

the appropriate amount of air flowing through the turbine, the

filter warning light will come on to indicate that it is time to

clean or change the filters.

i

The filter warning system does not shut down

the turbine.

Attention

Clean filters regularly. Clogged filters can cause

excessive heat and possibly damage the turbine.