13

FineCoat 9700

EN

1

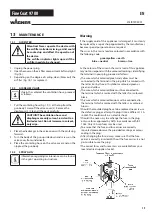

SAFETY REGULATIONS

All local safety regulations in force must be observed.

Read the operating instructions carefully and follow the in-

structions laid down in them in order to avoid risks.

1. Safety at the workplace

a) Keep your workplace clean and well lit.

Disorder or unlit workplaces may result in accidents.

b) Never use the tool in hazardous areas that contain

flammable liquids, gases or dusts.

Power tools generate

sparks that can ignite the dust or vapors.

c) Keep children and other persons away when using

the power tool.

You can lose control of the tool if you are

distracted.

2. Electrical Safety

a) The tool plug must fit into the socket. The plug may

not be modified in any form. Do not use adaptor plugs

together with protective-earthed tools.

Unmodified

plugs and suitable sockets reduce the risk of an electric shock.

b) Avoid physical contact with earthed surfaces such as

pipes, heating elements, stoves and refrigerators.

The

risk through electric shock increases if your body is earthed.

c) Keep the equipment away from rain and moisture.

The

risk of an electric shock increases if water penetrates electrical

equipment.

d) Do not misuse the mains lead by carrying the tool by

the lead, hanging it from the lead or by pulling on

the lead to remove the plug. Keep the lead away from

heat, oil, sharp edges or moving tool parts.

Damaged

or twisted leads increase the risk of an electric shock.

e) If you work outdoors with a power tool, only use

extension cables suitable for outdoor use.

The use of

an extension lead that is suitable for outdoors reduces the

risk of an electric shock.

f) ) If you cannot avoid using the tool in a damp

environment, use a residual current operated circuit-

breaker.

Using a residual current operated circuit-breaker

avoids the risk of electric shock.

3. Safety of Persons

a) Be attentive. Pay attention to what you are doing and

work sensibly with a power tool. Do not use the tool if

you are tired or under the influence of drugs, alcohol or

medication.

Just a moment of inattentiveness while using

the tool can lead to serious injuries.

b) Wear personal safety equipment and always wear

safety goggles.

Wearing personal protective equipment,

such as dust mask, non-slip safety shoes, safety helmet or

ear protection, depending on the type of power tools, reduces

the risk of injury.

c) Avoid accidental starting-up. Ensure that the switch

is in the “OFF” position before inserting the plug into

the socket.

Accidents can occur if you carry the power tool

while your finger is on the switch or if you connect the power

tool to the power supply which it is on.

d) Remove setting tools or wrenches before switching on

the power tool.

A tool or wrench that is in a rotating tool

part can lead to injuries.

e) Avoid an unnatural posture.

This ensures that you can

control the tool better in unexpected situations.

f) Wear suitable clothing. Do not wear wide clothing or

jewellery. Keep your hair, clothes and gloves away

from moving parts.

Loose clothing, jewellery or long hair

can be caught in moving parts.

g) Do not lull yourself into a false sense of security and

do not think yourself above the safety rules for electric

tools, even if you are familiar with the electric tool

following extensive practical experience.

Careless use

can lead to serious injuries in fractions of a second.

4. Careful Handling and Use of Power Tools

a) Do not overload the tool. Use the power tool designed

for the work that you are doing.

You work better and safer

in the specified performance range if you use the suitable

power tool.

b) Do not use power tools whose switch is defective.

A

power tool that cannot be switched on or off is dangerous

and has to be repaired.

c) Remove the plug from the socket before carrying out

tool settings, changing accessories or putting the tool

away.

This precautionary measure prevents unintentional

starting of the tool.

d) Store unused power tools so that they are inaccessible

to children. Do not let persons use the tool who

are not familiar with it or who have not read these

instructions.

Power tools are dangerous when they are used

by inexperienced persons.

e) Take proper care of your tools. Check whether the

moving parts function trouble-free and do not jam,

whether parts are broken or damaged so that the tool

function is impaired.

Have damaged parts repaired before

using the tool. Many accidents have their origin in power

tools that have been maintained badly.

f) Use the power tool, accessories, insert tools, etc. in

accordance with these instructions and in a fashion

specified for this special tool type. Take the working

conditions and the activity to be carried out into

consideration.

The use of power tools for purposes other

than the intended ones can lead to dangerous situations.

g) Keep the handles and grip surfaces dry, clean and

free of oil and grease.

Slippery handles and grip surfaces

hamper safe operation and control of the electric tool in

unforeseen situations.

5. Service

a) Have your tool repaired only by qualified specialist

SAFETY REGULATIONS

Summary of Contents for FINE COAT 9700

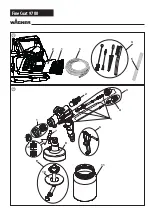

Page 3: ...FineCoat 9700 k h g m 3 10 cm n l Maximum Minimum Minimum i j A B 1 2...

Page 4: ...FineCoat 9700 q o t 1 r p 6 7 s 1 2 3 1 2 4 5 3 4...

Page 5: ...FineCoat 9700 2 1 3 4 5 1 8 2 3 5 6 7 9 10 11 4 12...

Page 111: ...105 FineCoat 9700 RU 1 1 a b c 2 a b c d e f 3 a b c d e f g...

Page 112: ...106 FineCoat 9700 RU 4 a b c d e f g 5 a b 1 2...

Page 113: ...107 FineCoat 9700 RU 3 4 3 5 6 1 4 13 2 7 8 9 10 11 12 13 14 15 16 17...

Page 118: ...112 FineCoat 9700 RU 12 1 1 2 3 13 13 1 1 2 18 3 18 1 13 2 1 19 1 2 3 2 3 4 13 3...

Page 119: ...113 FineCoat 9700 RU 14 30 13 2 3 1 13 1 13 1...