3

GB

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite. Severe

injury and/or property damage can occur.

PREVENTION

:

• Provide extensive exhaust and fresh air introduction

to keep the air within the spray area free from

accumulation of flammable vapors.

• Avoid all ignition sources such as static electricity

sparks, electrical appliances, flames, pilot lights, hot

objects, and sparks from connecting and disconnecting

power cords or working light switches.

• Plastic can cause static sparks. Never hang plastic

to enclose spray area. Do not use plastic drop cloths

when spraying flammable materials.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working

order.

• Power cord must be connected to a grounded circuit

(electric units only).

• Follow material and solvent manufacturer’s warnings

and instructions. Be familiar with the coating material’s

MSDS sheet and technical information to ensure safe

use.

• Use extreme caution when using materials with a

flashpoint below 70° F (21° C). Flashpoint is the

temperature that a fluid can produce enough vapors to

ignite.

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPATIBLE MATERIALS

Will cause severe injury or property damage.

PREVENTION

:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such

as methylene chloride and 1,1,1 - trichloroethane.

They are not compatible with aluminum and may

cause an explosion. If you are unsure of a material’s

compatibility with aluminum, contact your coating’s

supplier.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials

can be harmful if inhaled or come in contact with

body. Vapors can cause severe nausea, fainting, or

poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled.

Read all instructions supplied with the mask to be sure

it will provide the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating

manufacturer.

HAZARD: SKIN BURN INJURY

Heated parts can cause severe skin burn injury.

PREVENTION:

• Quick disconnect fittings on the hose and spray gun

become hot during use. Avoid skin contact with quick

disconnect fittings when they are hot. Allow quick

disconnect fittings to cool before disconnecting the

spray gun from the hose.

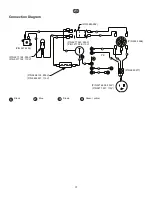

Earthing Instructions

PE

Electric models must be earthed. In the event of an

electrical short circuit, earthing reduces the risk of electric

shock by providing an escape wire for the electric current.

This product is equipped with a cord having an earthing

wire with an appropriate earthing plug. The plug must be

plugged into an outlet that is properly installed and earthed

in accordance with all local codes and ordinances.

DANGER — Improper installation of the earthing plug

can result in a risk of electric shock. If repair or

replacement of the cord or plug is necessary, do not

connect the green earthing wire to either blade

terminal. The wire with insulation having a green outer

surface with or without yellow stripes is the earthing

wire and must be connected to the earthing pin.

Check with a qualified electrician or serviceman if the earthing

instructions are not completely understood, or if you are in doubt as to

whether the product is properly earthed. Do not modify the plug provided.

If the plug will not fit the outlet, have the proper outlet installed by a

qualified electrician.

Caution – The power cord for this equipment acts as an

emergency stop/emergency switching off device. The

power cord must be placed near an easily accessible,

unobstructed socket-outlet.

Work or repairs at the electrical equipment:

These may only be carried out by a skilled electrician. No liability is

assumed for incorrect installation.

Power cord replacement must be performed by the manufacturer, its

service agent, or a similarly qualified person.

Operating Temperature

This equipment will operate correctly in its intended ambient, at a

minimum b10°C and +40°C.

Relative Humidity

The equipment will operate correctly within an environment at 50% RH,

+40°C. Higher RH may be allowed at lower temperatures.

Measures shall be taken by the Purchaser to avoid the harmful effects of

occasional condensation.

Altitude

This equipment will operate correctly up to 3000 m above mean sea level.

Transportation and Storage

This equipment will withstand, or has been protected against,

transportation and storage temperatures of -25°C to +55°C and for short

periods up to +70°C.

It has been packaged to prevent damage from the effects of normal

humidity, vibration and shock.

i

A list of the materials used in the construction of the

equipment will be made available on request to validate

compatibility with the coating materials to be used.

PE